The Versatile Solution for High-Quality Welding

Discuss Welding Wire Silicon

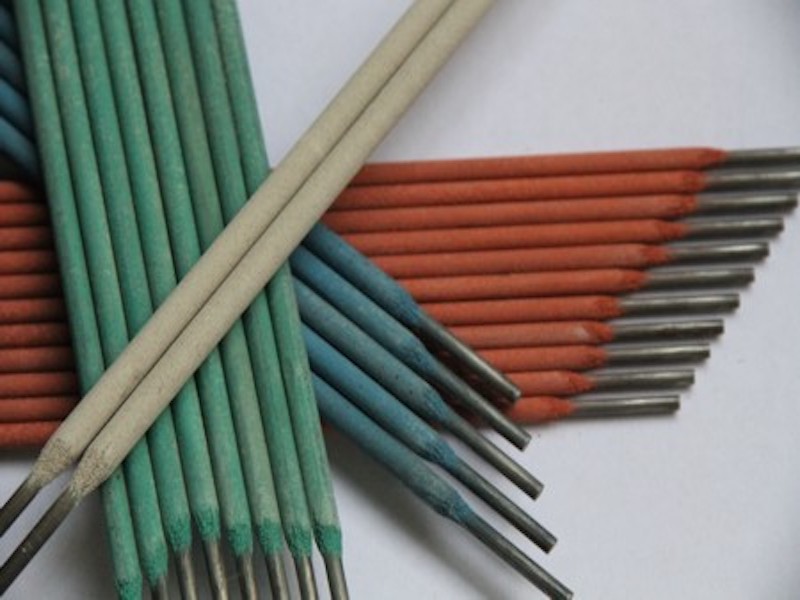

When it comes to welding, the quality of the welding wire used can have a significant impact on the overall welding process and the integrity of the final weld joint. One such welding wire that has gained popularity in recent years is welding wire silicon. It is a versatile solution that offers numerous benefits for different welding applications.

Welding wire silicon, also known as silicon bronze, is an alloy composed of copper, silicon, and a small percentage of other elements such as manganese, zinc, and tin. This combination results in a wire with excellent welding properties, making it highly desirable for various welding processes.

One of the key advantages of welding wire silicon is its high resistance to corrosion. This makes it an ideal choice for welding applications that involve materials that are prone to corrode, such as maritime structures, outdoor furniture, and architectural elements. The silicon content in the wire forms a protective oxide layer, shielding the weld joint from environmental factors that can cause corrosion.

In addition to its corrosion resistance, welding wire silicon offers excellent strength and ductility. This means that weld joints made with silicon bronze wire will be strong and able to withstand stress and strains without cracking or breaking. This makes it suitable for a wide range of applications, including art and sculpture welding, automotive repair, and sheet metal fabrication.

Buying Welding Wire Silicon

When purchasing welding wire silicon, it is essential to consider the specific requirements of your welding project. The diameter of the wire, as well as the type and thickness of the materials you will be welding, should all be taken into account.

Silicon bronze wire is available in various diameters, ranging from 0.030 inches to 1/8 inches or even larger. Thinner wires are commonly used for delicate welding projects, such as fine art sculptures or jewelry, while thicker wires are typically employed for heavy-duty applications.

When selecting the type of welding wire silicon, it is crucial to opt for a high-quality product from a reputable supplier. Ensure that the wire meets industry standards and certifications, such as the American Welding Society (AWS) specifications, to guarantee its performance and reliability.

Price of Welding Wire Silicon

The price of welding wire silicon can vary depending on several factors, including the diameter, quantity, brand, and supplier. As with any welding consumable, it is essential to balance cost with quality and ensure that you are purchasing a product that meets your specific welding needs.

Generally, silicon bronze wire is priced competitively, making it an affordable option for many welding applications. However, it is crucial to consider the overall value and performance of the wire rather than solely focusing on the price. Investing in high-quality welding wire can deliver better weld results and reduce the risk of weld failures, which can ultimately save time, money, and effort in the long run.

To get the best price for welding wire silicon, consider comparing prices from different suppliers and evaluating the quality and performance of their products. Look for testimonials or reviews from other welders who have used the specific wire you are considering to gain insights into its performance and reliability.

Furthermore, some suppliers may offer bulk discounts or have promotions, so it is worthwhile to inquire about any ongoing deals or special offers. However, always prioritize quality and ensure that the wire you purchase meets your welding requirements, as inexpensive wire that compromises on quality can result in subpar welds.

In conclusion, welding wire silicon is a versatile and high-performing solution for various welding applications. Its resistance to corrosion, high strength, and ductility make it an ideal choice for welders looking to achieve durable and reliable weld joints. When purchasing welding wire silicon, consider the specific requirements of your project, including diameter and material type, and choose a high-quality product from a reputable supplier. While the price of the wire is an important consideration, it should not be the sole determining factor. Investing in quality welding wire will ensure better weld results and reduce the risk of weld failures in the long term, ultimately saving time, money, and effort.