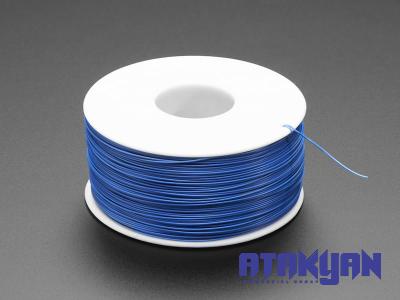

When it comes to welding, the choice of welding wire gauge is crucial in ensuring a successful and efficient welding process. A welding wire gauge refers to the thickness of the wire that is used in welding operations. The gauge of the wire determines its diameter and plays a significant role in the quality of the weld and the overall welding performance. Understanding the concept of welding wire gauge is essential for welders of all levels, from beginners to experienced professionals. In welding applications, the gauge of the wire is specified using a numerical value that corresponds to a specific diameter. The higher the gauge number, the thinner the wire, while lower gauge numbers indicate thicker wires. This relationship is crucial to grasp as it directly influences the welding process and the final weld quality.

.

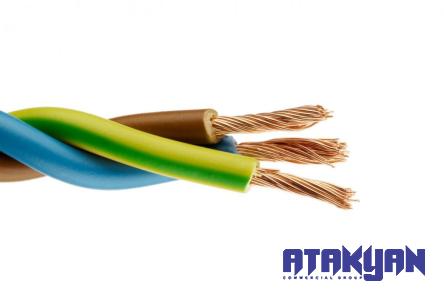

Effective utilization of welding wire gauge involves more than just choosing the correct diameter. It also requires a deep understanding of how different wire gauges interact with various welding parameters to achieve the desired welding outcome. Experimenting with different wire gauges in different welding scenarios can enhance a welder’s skills and broaden their knowledge base. Furthermore, staying abreast of advancements in welding wire technology and understanding the latest trends in wire gauge applications can give welders a competitive edge in the industry. New developments in wire manufacturing techniques and alloy compositions can offer improved welding characteristics, better weld bead appearance, and enhanced welding efficiency. Moreover, awareness of the limitations and capabilities of each welding wire gauge is crucial for welders to troubleshoot welding issues effectively. For instance, using a wire gauge that is too thin for a particular welding application may lead to inadequate weld penetration and weak weld strength. Conversely, using a wire gauge that is too thick can result in excessive heat input, excess spatter, and potential distortion of the base metal.

Effective utilization of welding wire gauge involves more than just choosing the correct diameter. It also requires a deep understanding of how different wire gauges interact with various welding parameters to achieve the desired welding outcome. Experimenting with different wire gauges in different welding scenarios can enhance a welder’s skills and broaden their knowledge base. Furthermore, staying abreast of advancements in welding wire technology and understanding the latest trends in wire gauge applications can give welders a competitive edge in the industry. New developments in wire manufacturing techniques and alloy compositions can offer improved welding characteristics, better weld bead appearance, and enhanced welding efficiency. Moreover, awareness of the limitations and capabilities of each welding wire gauge is crucial for welders to troubleshoot welding issues effectively. For instance, using a wire gauge that is too thin for a particular welding application may lead to inadequate weld penetration and weak weld strength. Conversely, using a wire gauge that is too thick can result in excessive heat input, excess spatter, and potential distortion of the base metal.

..

By honing their skills in selecting and using welding wire gauges appropriately, welders can elevate the quality of their work and set themselves apart as proficient craftsmen in the welding industry. A comprehensive understanding of welding wire gauge empowers welders to tackle complex welding projects with ease, deliver superior welding results, and build a reputation as skilled professionals in their field. In conclusion, welding wire gauge is an indispensable component of the welding process that influences weld quality, performance, and overall welding success. By familiarizing themselves with the nuances of different wire gauges, welders can make informed decisions when selecting the most suitable wire for their welding projects. Embracing the complexities of welding wire gauge and its impact on welding parameters equips welders with the knowledge and expertise needed to excel in the craft of welding and achieve exceptional welding outcomes.

By honing their skills in selecting and using welding wire gauges appropriately, welders can elevate the quality of their work and set themselves apart as proficient craftsmen in the welding industry. A comprehensive understanding of welding wire gauge empowers welders to tackle complex welding projects with ease, deliver superior welding results, and build a reputation as skilled professionals in their field. In conclusion, welding wire gauge is an indispensable component of the welding process that influences weld quality, performance, and overall welding success. By familiarizing themselves with the nuances of different wire gauges, welders can make informed decisions when selecting the most suitable wire for their welding projects. Embracing the complexities of welding wire gauge and its impact on welding parameters equips welders with the knowledge and expertise needed to excel in the craft of welding and achieve exceptional welding outcomes.

…

In essence, the key to mastering welding wire gauge lies in continuous learning, practice, and hands-on experience. By immersing themselves in the world of welding wire gauges, welders can refine their skills, expand their knowledge, and elevate the quality of their welds to new heights. With a solid foundation in welding wire gauge fundamentals, welders can embark on a journey of exploration and innovation, pushing the boundaries of their welding capabilities and creating flawless welds that stand the test of time.

In essence, the key to mastering welding wire gauge lies in continuous learning, practice, and hands-on experience. By immersing themselves in the world of welding wire gauges, welders can refine their skills, expand their knowledge, and elevate the quality of their welds to new heights. With a solid foundation in welding wire gauge fundamentals, welders can embark on a journey of exploration and innovation, pushing the boundaries of their welding capabilities and creating flawless welds that stand the test of time.

Your comment submitted.