A Comprehensive Guide

Introduction:

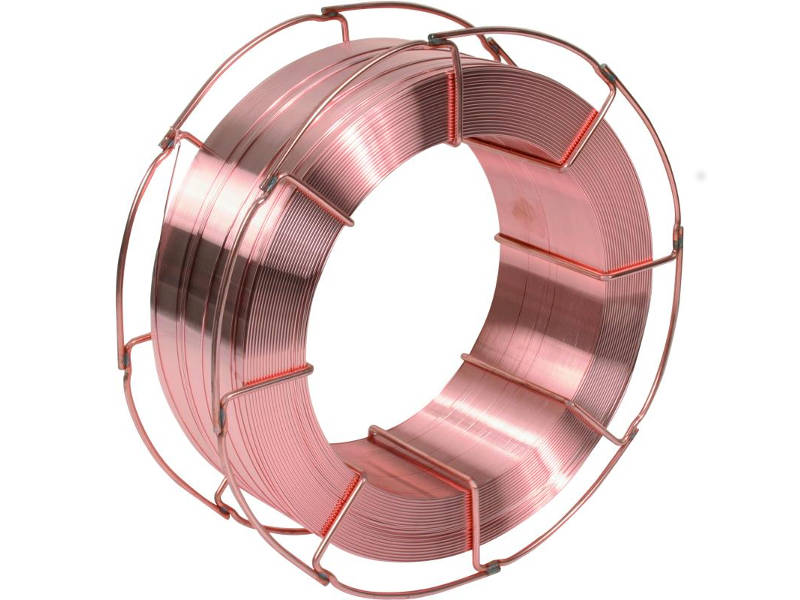

Welding galvanized steel can be a challenging task due to the unique properties of the material. To overcome these challenges, using the right welding wire is crucial. In this article, we will discuss the characteristics of welding wire for galvanized steel, factors to consider when buying it, and the price range you can expect in the market.

Discuss Welding Wire for Galvanized Steel:

When it comes to welding galvanized steel, you need to choose a welding wire that is specifically designed for this type of metal. Galvanized steel is coated with a layer of zinc, which provides corrosion resistance. However, this zinc coating can present challenges during the welding process.

Welding on galvanized steel produces zinc oxide fumes, which can be harmful if inhaled. Therefore, it is important to choose a welding wire that is formulated to handle this challenge. The ideal wire should possess properties that guard against excessive spattering, porosity, and other issues caused by zinc evaporation during the welding process.

Buying Welding Wire for Galvanized Steel:

When purchasing welding wire for galvanized steel, several key factors should be taken into consideration to ensure optimal results.

1. Zinc Content: Look for wires with low levels of zinc in their composition. Higher zinc content can lead to increased spatter and porosity during welding. Choose wires with a zinc content of 0.15% or lower for better performance.

2. Wire Diameter: The diameter of the welding wire should match the thickness of the galvanized steel being welded. Thinner wires are suitable for thinner materials, while thicker wires provide better penetration for thicker galvanized steel.

3. Flux Core or Solid Wire: Consider whether you need a flux core or solid wire for your welding project. Flux core wires contain a flux material within the core of the wire, which provides shielding gas and helps remove impurities during the welding process. Solid wires require external shielding gas. Flux core wires are generally recommended for welding galvanized steel as they provide better protection against zinc evaporation.

4. Brand and Quality: Choose a reputable brand that specializes in welding wire for galvanized steel. Well-established brands are more likely to produce high-quality wires that have been thoroughly tested and proven effective for welding galvanized steel.

Price of Welding Wire for Galvanized Steel:

The price of welding wire for galvanized steel can vary depending on various factors such as brand, wire diameter, and quantity. Generally, the price range for welding wire suitable for galvanized steel falls between $0.50 to $1.50 per pound.

Higher-quality welding wires may come at a slightly higher price but can offer better performance, reducing the risk of spattering and porosity. It is worth investing in a higher-quality wire if you have critical welding projects or if you frequently work with galvanized steel.

While it might be tempting to opt for cheaper alternatives, it is important to consider the potential issues that could arise from using subpar welding wire. Poor-quality wire may result in increased porosity, lack of fusion, and compromised weld integrity.

Conclusion:

Selecting the right welding wire for galvanized steel is essential to ensure the integrity and quality of your welds. By considering factors such as zinc content, wire diameter, flux core or solid wire, and brand reputation, you can be confident in your choice of welding wire. Investing in a high-quality welding wire may come at a higher price, but it is worth it to achieve reliable and durable welding results.In conclusion, when it comes to welding galvanized steel, using the appropriate welding wire is crucial for achieving strong and reliable welds. By understanding the challenges posed by welding on galvanized steel and considering important factors such as zinc content, wire diameter, flux core or solid wire, and brand reputation, you can make an informed decision when purchasing welding wire for galvanized steel.

It is worth noting that welding wire for galvanized steel is available in a wide range of prices. While it may be tempting to opt for the cheapest option, it is important to consider the potential consequences of using low-quality wire. Investing in a higher-quality welding wire may cost a bit more, but it can greatly reduce the risk of issues such as excessive spattering, porosity, and lack of fusion.

When selecting a brand, it is advisable to opt for well-established manufacturers that specialize in welding wire for galvanized steel. These brands have a reputation to uphold and are more likely to produce high-quality wires that have undergone thorough testing.

Remember to match the wire diameter to the thickness of the galvanized steel being welded. Using the appropriate wire diameter ensures proper penetration and weld integrity. Additionally, selecting the right type of wire, whether flux core or solid, based on your specific welding requirements is crucial.

By taking these factors into consideration, you can ensure that the welding wire you choose is specifically designed to handle the challenges presented by galvanized steel. This will ultimately result in improved welding performance and higher-quality welds.

In summary, welding wire for galvanized steel plays a significant role in the overall welding process. By using the right wire, you can overcome the challenges posed by the zinc coating, minimize the risk of defects in the welds, and achieve strong and durable results. When purchasing welding wire for galvanized steel, prioritize factors such as zinc content, wire diameter, flux core or solid wire, and brand reputation to make an informed decision. Investing in high-quality welding wire is a worthwhile investment that will ultimately save you time, effort, and potential rework in the long run.