Wire brushes are an essential tool for duplex, arc, and saw weld cleaning. They’re adaptable and excellent at removing surface contamination like rust or heat discoloration without removing the foundation material. Wire brushes come in a variety of shapes and sizes, each with its own set of advantages and best practices for use. Let’s discuss how to choose the correct wire brush for your application and offer some techniques for enhancing productivity in weld cleaning.

Using the proper welding consumables or filler material results in a strong bond between the two metals involved. These are one of the four most critical components of welding, together with the metal to be utilized, the source of heat, and the air shield. When the metal is heated to its melting temperature while being sheltered from the air, the consumable is applied to the spot that will be bonded together to produce a single piece of metal. Consumables in arc welding not only serve as a filler during the heating process but also aid in flame stabilization.

Cast items utilized in the chemical, marine, and other engineering industries dominated the first 50 years of duplex stainless-steel technology. Several national specifications (e.g., ASTM A351, A744 – CD4MCu) and proprietary alloys (e.g., Ferralium 255) were established during this time period. Welding upgrades were unavoidable, and the standard procedure was to employ “matching composition” consumables followed by a solution treatment plus water quench.

The submerged arc technique is unique in that, unlike other fluxed processes such as MMA or FCAW, the welding consumables consist of two components, the wire and the flux, which can be supplied separately.

Because both the wire and the flux affect the weld metal composition and hence the mechanical qualities, the welding engineer must select the best wire/flux combination for the application. This article goes over some of the properties of wires and fluxes. The specifications will be discussed in the following article.

Welding Wire Brush

To remove slag, rust, and other contaminants from the welding surface, a wire brush is typically utilized. The bristles of the brush are made of stainless steel.

When working with stainless steel, you should always use a chipping hammer made of stainless steel as well as a brush with stainless steel bristles.

The wire brush is essentially an abrasive tool that is utilized for the purposes of stripping paint and cleaning up rust. It can also be used to clean surfaces and to produce a more conducive area for making electrical connections. One example of this would be the connections between car battery posts and their connectors, which can accumulate a buildup of filth and dirt over time. When cleaning stainless steel, it is best to use a bristle wire brush made of stainless steel. This is because using a brush made of plain carbon steel might contaminate the stainless steel, leading to the appearance of rust spots. On softer surfaces or in potentially combustible locations where non-sparking equipment is necessary, brass bristle brushes are used instead of other types of brushes. The teeth of giant animals, such as crocodiles and pigs, can also be cleaned with wire brushes. Examples of these animals include They are also commonly employed in the field of surface engineering, namely for cleaning castings before painting them. It is normal practice to utilize powered wire brushes for the purpose of creating brushed metal and deburring edges.

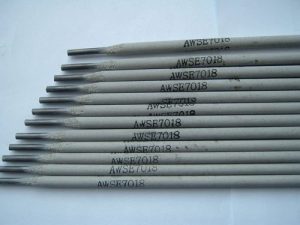

Arc Welding Consumables

In arc welding, a flow of electrons is used to heat metallic workpieces in a localized area to generate a molten puddle that is referred to as the “weld pool.” This process is referred to as “the arc,” and it is known by its acronym. After the arc has moved on or been withdrawn, the weld pool will begin to solidify, which will result in a bond being formed between the pieces that were previously separate.

There are two primary categories of welding consumables: the first category includes elements that are included in the weld itself (often referred to as “filler metal”), and the second category contains components that are used up in the course of the welding process. In this piece, we will spend our primary emphasis on the consumable components that make it possible to weld, with particular consideration is given to the MIG/MAG, TIG, and MMA procedures.

Filler materials, also known as consumables, are the types of materials that are utilized in welding. These chemicals, as their name suggests, provide either a filler or a body of molten materials that allows for a strong bond to be created between the base metals that are utilized. The majority of welding methods will also need some kind of shielding in order to prevent the primary components and the filler from getting oxidized while the process is being carried out.

The term “parent material” refers to the metallic components that are brought together during the process of welding. Consumables are the substance that is added in order to assist in the formation of this joint. Because of the various forms that these materials can take, they may be referred to by names such as parent plate or pipe, filler wire, consumable electrode (for arc welding), and so on.

Duplex Welding Consumables

Wrought duplex stainless steel was first widely used in the offshore oil and gas industries about 20 years ago. Then they were used in more diverse applications because of their exceptional blend of corrosion resistance and superior mechanical qualities. They are currently the third most utilized grade of stainless steel in Europe. However, cast goods that were utilized for pump casings, valve bodies, and other various applications in the chemical and marine sectors dominated the previous 50 years of duplex stainless-steel technology. Several national requirements developed at this time, and a considerable number of exclusive alloys were created. As with most alloy castings, welding was inevitably needed for upgrading, repairs, and joining. A conventional technique called for utilizing welding supplies whose composition roughly matched that of the parent alloy, followed by solution treatment and water quench. These procedures have recently been expanded to include thick-walled process pipework and vessel heads in addition to castings, all of which require complete heat treatment after welding and are sufficiently substantial to prevent or minimize any distortion that may happen during heating and/or quenching. There has been a lot of interest in using overmatching consumables, which are typically only used as welded-on wrought steels, in order to streamline work processes and procedures, decrease inventories, and in certain circumstances, increase toughness at sub-zero temperatures (below -50°C).

Given the proper welding techniques and heat treatments, it is presently thought that using overmatching consumables is a realistic option that can result in better characteristics.

Saw Welding Consumables

A typical arc welding procedure is submerged arc welding (SAW). In 1935, the first SAW patent was obtained. A continuously fed consumable solid or tubular (metal cored) electrode is necessary for the process. The molten weld and the arc zone are “submerged” under a blanket of granular fusible flux made of lime, silica, manganese oxide, calcium fluoride, and other substances to protect them from ambient pollution. The flux creates a current path between the electrode and the work as it melts and turns conductive. The shielded metal arc welding (SMAW) procedure uses a thick coating of flux to completely cover the molten metal, preventing spatter and sparks as well as suppressing powerful ultraviolet radiation and gases.

The granulated flux acts as a shield, preventing ambient contaminants from reaching the molten weld. The flux can alter the chemical composition of the weld metal while also cleaning it. The flow is divided into discrete sizes. It could be mechanically combined, fused, or bonded. Fluorides of calcium as well as calcium, magnesium, silicon, aluminum, and manganese oxides could be present in the flux. Adding alloying components is possible based on the needs. During welding, no materials that release a lot of gases are ever combined with the flux. For welding thicker and thinner materials, respectively, flux with fine and coarse particle sizes is advised.

Typically, a normal wire and additional unique forms make up the SAW filler material. Usually, this wire is between 1.6 and 6 mm (1/16 to 1/4) thick. The twisted wire can be employed in some situations to give the arc an oscillating motion. This aids in joining the base metal at the weld’s toe. The material being welded determines the composition of the electrode.

Plastic Welding Consumables

Plastic welders come in different types. Welding systems and power sources are examples. Brazing, cutting, soldering, and/or surfacing subsystems are included. They also have a power supply or station, torch, iron, gun, wires, feeds, positioners, and robots. Plastic welders are powered by a soldering iron, TIG gun, MIG gun, laser, electrode holder, electron beam gun, or similar joining device. The output power melts the substance. Welding power sources are for plastic welding systems. Soldering stations supply soldering power.

Plastic welders have weapons and monitors. Irons, torches, or plastic welder guns melt solder or filler alloys at a joint or interface. Electrical resistance heats soldering irons. Gas torches or hot air-heated irons can be used in plumbing or field applications without an electrical supply. Brazing and welding use gas, oxy-fuel, and plasma torches. Monitors/controllers sense joint quality (size or integrity), gap, location, or output power supply fluctuations. Plastic welder controllers modify parameters to compensate for joint quality or output power variations.

Plastic welders use frictional or specialized procedures, including ultrasonic welding, gas torch brazing, hot rod or iron welding, and laser welding. Friction welding heats workpieces by surface motion. Ultrasonic vibration of linear friction welding heats the workpieces. Gas torch brazing uses propane, air, or oxygen to heat the workpiece and melt the filler alloy. Other brazing and soldering methods use a heated rod or iron to melt solder filler-alloy. Laser welding melts the workpiece. No filler metals or consumable electrodes are needed. Other plastic welders exist.

Robotic Welding Consumables

The objective of investing in automation is to increase production and quality, which will differentiate your welding operation from the competition and boost your bottom line. However, to be successful with an automated welding system, you must make sure that the parts you are welding are uniform and repeatable, check to see whether your welding operation has a strong workflow, and have welding operators who are properly trained to manage the system. Additionally, it would help if you had the appropriate tools for the work.

It would help if you carefully choose the appropriate robotic MIG gun and consumables, such as contact tips, nozzles, liners, and retention heads, for the application, in addition to working with a trustworthy robotic integrator to choose and implement the robot. The consumables are an easily disregarded component of an automated welding system, but they can have a quantifiable effect on downtime and ongoing expenses. Consider these recommendations to obtain the maximum performance out of these components.

Depending on the application, the contact-tip-to-nozzle relationship for an automated welding system varies, but it still affects the welding performance and quality you accomplish. Applications with intricate tooling or joints frequently need a long contact-tip-to-nozzle interaction. You can access more complicated joints with this relationship and can more easily accept complex tooling. It would be beneficial if you were aware of the fact that because of this link, your contact tip is more likely to accumulate spatter and may have a shorter lifespan because it is exposed to the arc’s heat. Applying an anti-spatter solution can provide some defense against these circumstances, but you’ll also need to check your contact tips frequently for wear and tear; in order to solve issues, keep in mind that preventive maintenance is preferable to downtime. Replace your contact tips before problems arise.

Your comment submitted.