Stainless steel is a widely-used material known for its durability, corrosion resistance, and aesthetic appeal. It is commonly used in various industries such as construction, automotive, aerospace, and more. One of the key processes involved in working with stainless steel is welding. Welding stainless steel requires specific techniques and equipment to ensure a strong and clean weld. In this guide, we will delve into the specifications of welding stainless steel and explore how to buy stainless steel in bulk for your welding projects.

.

Before diving into the welding process, it is essential to understand the specifications of the stainless steel you will be working with. Stainless steel is available in different grades, each with its own unique properties. The most common grades used for welding include 304, 316, and 430 stainless steel. When welding stainless steel, it is crucial to consider factors such as the grade of stainless steel, welding method, filler material, and shielding gas. The choice of welding method depends on the thickness of the stainless steel and the desired welding outcome. The most common welding methods used for stainless steel include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and stick welding.

Before diving into the welding process, it is essential to understand the specifications of the stainless steel you will be working with. Stainless steel is available in different grades, each with its own unique properties. The most common grades used for welding include 304, 316, and 430 stainless steel. When welding stainless steel, it is crucial to consider factors such as the grade of stainless steel, welding method, filler material, and shielding gas. The choice of welding method depends on the thickness of the stainless steel and the desired welding outcome. The most common welding methods used for stainless steel include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and stick welding.

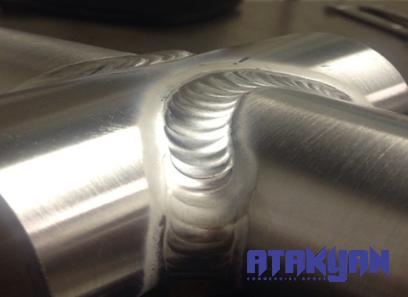

TIG welding is often preferred for welding stainless steel as it provides precise control over the welding process, producing clean and high-quality welds. MIG welding, on the other hand, is faster and more suitable for large-scale welding projects. Stick welding is commonly used for welding thicker stainless steel sections. The selection of filler material is critical when welding stainless steel. Matching the filler material with the base metal is essential to achieve a strong and corrosion-resistant weld. For welding 304 stainless steel, a filler material such as 308L or 309L is commonly used. For welding 316 stainless steel, 316L filler material is recommended. It is crucial to avoid cross-contamination of filler materials to maintain the integrity of the weld.In

..

When purchasing stainless steel in bulk for welding projects, it is advisable to establish a long-term relationship with a reputable supplier who can provide consistent quality materials, reliable delivery schedules, and competitive pricing. Building a strong partnership with a reliable supplier can streamline the procurement process, reduce lead times, and ensure a steady supply of stainless steel for ongoing welding projects. Lastly, conducting regular quality checks and inspections of the stainless steel material upon receipt is essential to verify compliance with specifications and standards. Performing tests such as material composition analysis, hardness testing, and visual inspections can help identify any discrepancies or defects in the material before initiating the welding process.

When purchasing stainless steel in bulk for welding projects, it is advisable to establish a long-term relationship with a reputable supplier who can provide consistent quality materials, reliable delivery schedules, and competitive pricing. Building a strong partnership with a reliable supplier can streamline the procurement process, reduce lead times, and ensure a steady supply of stainless steel for ongoing welding projects. Lastly, conducting regular quality checks and inspections of the stainless steel material upon receipt is essential to verify compliance with specifications and standards. Performing tests such as material composition analysis, hardness testing, and visual inspections can help identify any discrepancies or defects in the material before initiating the welding process.

…

In conclusion, buying stainless steel in bulk for welding projects requires careful consideration of factors such as grade, quality, dimensions, and supplier reliability. By understanding the specific requirements of the welding applications and collaborating with a trusted supplier, businesses and individuals can source high-quality stainless steel materials for their projects with confidence and efficiency. Welding stainless steel offers endless possibilities for creating strong, durable, and visually appealing structures and products, making it a valuable material choice for a wide range of industries.

In conclusion, buying stainless steel in bulk for welding projects requires careful consideration of factors such as grade, quality, dimensions, and supplier reliability. By understanding the specific requirements of the welding applications and collaborating with a trusted supplier, businesses and individuals can source high-quality stainless steel materials for their projects with confidence and efficiency. Welding stainless steel offers endless possibilities for creating strong, durable, and visually appealing structures and products, making it a valuable material choice for a wide range of industries.

Your comment submitted.