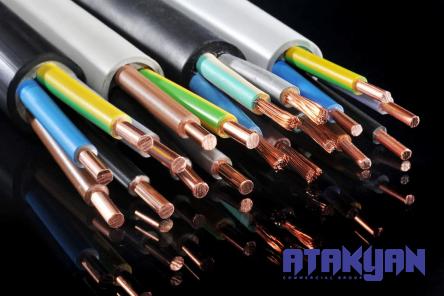

In the realm of welding, the choice of cable wire is crucial in ensuring the efficiency and safety of the welding process. Welding machine cable wire is a vital component that facilitates the flow of electricity from the power source to the welding gun, allowing for the creation of strong, durable welds. Whether you are a professional welder, a hobbyist, or a business owner in need of welding supplies, understanding the specifications of welding machine cable wire and how to purchase it in bulk is essential for a seamless welding experience. Welding machine cable wire comes in various sizes and materials, each designed to suit different welding applications. One of the key specifications to consider when choosing welding cable wire is the gauge or thickness of the wire. Thicker cables have a lower gauge number and are ideal for high-amperage welding applications that require increased current carrying capacity. Conversely, thinner cables with a higher gauge number are suitable for low-amperage welding tasks. It is important to match the cable wire gauge to the amperage of your welding machine to ensure optimal performance and safety.

.

One of the primary benefits of buying welding machine cable wire in bulk is cost savings. Suppliers often offer discounts or special pricing for bulk orders, allowing you to save money on your overall purchase. By buying in larger quantities, you can take advantage of economies of scale and negotiate better pricing with suppliers. This can result in significant cost savings over time, especially for businesses that have high welding machine cable wire consumption. In addition to cost savings, buying welding machine cable wire in bulk can also help streamline your welding operations and reduce downtime. Having a large supply of cable wire on hand ensures that you always have the necessary materials available to fulfill welding orders and complete projects on time. This can be particularly advantageous for businesses that have a high volume of welding work or operate in industries where welding is a key part of the production process.

One of the primary benefits of buying welding machine cable wire in bulk is cost savings. Suppliers often offer discounts or special pricing for bulk orders, allowing you to save money on your overall purchase. By buying in larger quantities, you can take advantage of economies of scale and negotiate better pricing with suppliers. This can result in significant cost savings over time, especially for businesses that have high welding machine cable wire consumption. In addition to cost savings, buying welding machine cable wire in bulk can also help streamline your welding operations and reduce downtime. Having a large supply of cable wire on hand ensures that you always have the necessary materials available to fulfill welding orders and complete projects on time. This can be particularly advantageous for businesses that have a high volume of welding work or operate in industries where welding is a key part of the production process.

..

Furthermore, purchasing welding machine cable wire in bulk can improve your inventory management and supply chain efficiency. By buying in larger quantities, you can reduce the frequency of reordering and minimize the risk of running out of essential materials. This can help you better plan and forecast your welding needs, ensuring that you always have an adequate supply of cable wire on hand to meet customer demands and business requirements. When buying welding machine cable wire in bulk, it is important to consider the storage and handling of the materials to maintain their quality and performance. Proper storage of cable wire in a clean, dry environment away from moisture and extreme temperatures can help prevent damage and ensure the longevity of the materials. Additionally, handling the cable wire with care and avoiding sharp bends or kinks can preserve the flexibility and integrity of the wires for optimal performance in welding applications.

Furthermore, purchasing welding machine cable wire in bulk can improve your inventory management and supply chain efficiency. By buying in larger quantities, you can reduce the frequency of reordering and minimize the risk of running out of essential materials. This can help you better plan and forecast your welding needs, ensuring that you always have an adequate supply of cable wire on hand to meet customer demands and business requirements. When buying welding machine cable wire in bulk, it is important to consider the storage and handling of the materials to maintain their quality and performance. Proper storage of cable wire in a clean, dry environment away from moisture and extreme temperatures can help prevent damage and ensure the longevity of the materials. Additionally, handling the cable wire with care and avoiding sharp bends or kinks can preserve the flexibility and integrity of the wires for optimal performance in welding applications.

…

In conclusion, purchasing welding machine cable wire in bulk offers numerous benefits for individuals and businesses in the welding industry. By understanding the specifications of cable wire, working with reputable suppliers, and taking advantage of cost savings and efficiency improvements, you can enhance your welding operations and achieve superior welds. Investing in high-quality welding machine cable wire in bulk quantities is a strategic decision that can drive productivity, cost savings, and success in the welding industry.

In conclusion, purchasing welding machine cable wire in bulk offers numerous benefits for individuals and businesses in the welding industry. By understanding the specifications of cable wire, working with reputable suppliers, and taking advantage of cost savings and efficiency improvements, you can enhance your welding operations and achieve superior welds. Investing in high-quality welding machine cable wire in bulk quantities is a strategic decision that can drive productivity, cost savings, and success in the welding industry.

Your comment submitted.