A Comprehensive Guide to Choosing the Right Option

Introduction:

Welding is a crucial process in various industries, ranging from manufacturing to construction. To achieve strong and reliable welds, it is essential to use the appropriate welding electrodes. With numerous electrodes available in the market, it can be daunting to choose the right type for your specific application. In this article, we will dive into the different types of welding electrodes, factors to consider when buying them, and an overview of their pricing.

Discuss Welding Electrodes Types:

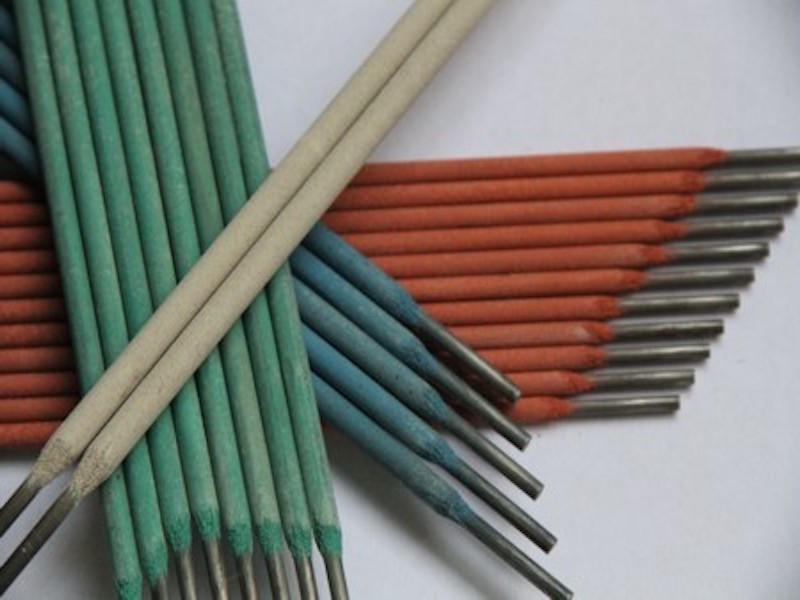

Welding electrodes are primarily categorized into three types: shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW).

1. Shielded Metal Arc Welding (SMAW) Electrodes:

SMAW electrodes, also known as stick electrodes, are widely used due to their versatility. The stick electrodes are coated with flux that melts during the welding process, creating a protective shielding gas and slag. This slag protects the molten weld pool from contamination, resulting in high-quality welds. SMAW electrodes are suitable for welders of all skill levels and can be used on various materials, such as carbon steel, stainless steel, and cast iron.

2. Gas Metal Arc Welding (GMAW) Electrodes:

GMAW electrodes, commonly referred to as MIG (metal inert gas) or MAG (metal active gas) electrodes, utilize a continuous wire feed. They provide a clean and efficient welding process, making them ideal for automotive, fabrication, and construction industries. GMAW electrodes work by using a shielding gas, such as argon or a mixture of argon and carbon dioxide, to protect the weld from atmospheric contamination. They produce excellent welds on materials like aluminum, mild steel, and stainless steel.

3. Flux-Cored Arc Welding (FCAW) Electrodes:

FCAW electrodes combine the benefits of SMAW and GMAW processes. The flux inside the electrode creates a shielding gas and produces a slag, similar to SMAW, while the continuous wire feed offers the efficiency of GMAW. FCAW electrodes are often used in heavy-duty applications, including construction, shipbuilding, and pipelines. They provide deep penetration and can be used on thick materials, making them suitable for welding in outdoor and windy conditions.

Buying Welding Electrodes Types:

When purchasing welding electrodes, there are several factors to consider, including:

1. Material Compatibility: The first step is to ensure the welding electrode is compatible with the material you intend to weld. Different electrodes are designed for specific materials, such as carbon steel, stainless steel, or aluminum. Choosing the wrong electrode can result in weak welds or damage to the material.

2. Electrode Diameter: Welding electrodes are available in various diameters, typically ranging from 1.6mm to 6mm. The diameter selection depends on the thickness of the material and the welding application. Smaller diameter electrodes are suitable for thin materials, while larger diameters are better for thicker metals.

3. Current Type: The type of current used during the welding process influences the choice of electrodes. For instance, DC current is commonly used for SMAW electrodes, while AC or DC can be used for GMAW and FCAW electrodes. It is crucial to determine the appropriate current type based on the welding equipment and materials you are working with.

Price of Welding Electrodes Types:

The prices of welding electrodes can vary depending on factors such as brand, type, and quantity. SMAW electrodes are generally more affordable compared to GMAW and FCAW electrodes. However, the cost of electrodes should not be the sole determining factor when making a purchasing decision. Consider the quality, performance, and suitability for your specific welding needs when assessing the price.

Additionally, keep in mind that cheaper electrodes may have lower quality coatings, resulting in increased spatter, lower deposition rates, and compromised weld quality. It is important to strike a balance between affordability and quality to ensure optimal welding results.

Conclusion:

Choosing the right welding electrodes is essential for achieving strong, durable, and high-quality welds. Understanding the types of electrodes available, considering factors such as material compatibility, electrode diameter, and current type, will help you make an informed decision. Remember, while price is an important factor, it should not be the only consideration. Invest in reliable and suitable welding electrodes to ensure successful welding projects that stand the test of time.