Finding the Right Fit for Your Welding Needs

Welding electrodes are essential tools in the welding industry. They are designed to conduct electricity to the workpiece while creating an arc that generates intense heat, which in turn melts the metal. A key factor to consider when selecting welding electrodes is the size, as it directly affects the outcome of the welding process. In this article, we will discuss the importance of welding electrode size, how to choose the right size for your welding project, and considerations regarding the price of welding electrodes size.

Discuss Welding Electrodes Size

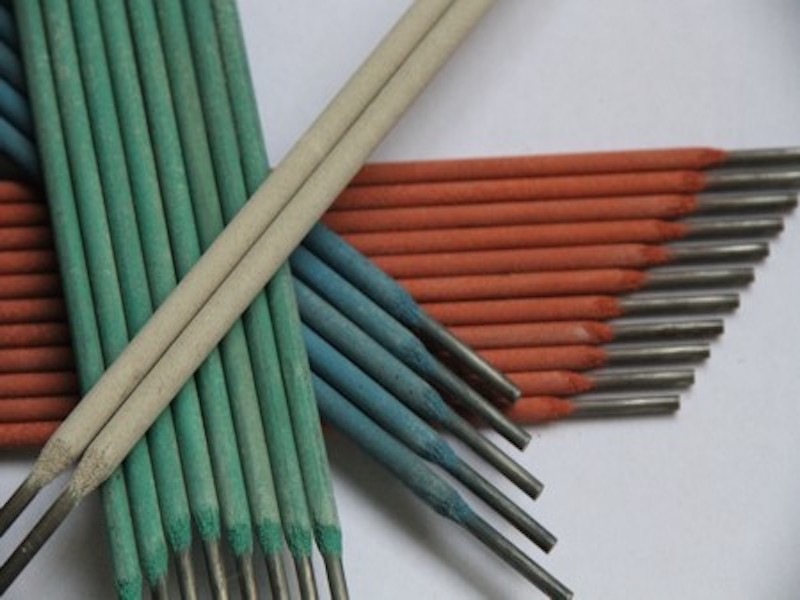

Welding electrodes come in various sizes, which are typically indicated by a number known as the electrode’s “diameter.” The diameter refers to the thickness of the metal core of the electrode. It is a crucial characteristic to consider as it determines the current-carrying capacity, arc stability, penetration depth, and deposition rate.

The size of the welding electrode significantly impacts the welding process. Smaller diameter electrodes, such as 2.5mm or 3.2mm, are suitable for thinner materials and delicate welds. They require lower amperage and allow for precise control over the welding parameters. On the other hand, larger diameter electrodes, such as 4.0mm or 5.0mm, are better suited for thicker materials and heavy-duty applications, as they can provide higher deposition rates and deeper penetration.

Choosing the right welding electrode size is crucial for achieving desired weld quality and meeting project requirements. Proper consideration must be given to factors such as the type of material being welded, welding position, joint design, and welding amperage.

Buying Welding Electrodes Size

When purchasing welding electrodes, it is essential to understand the welding electrode classification system that determines their size. The American Welding Society (AWS) and the International Organization for Standardization (ISO) have established guidelines and standards to aid buyers in selecting the appropriate size.

The classification system typically consists of a four or five-digit code. The first two digits indicate the tensile strength of the weld metal, followed by a letter representing the welding position, another digit, and possibly a suffix letter to indicate specific requirements.

For instance, an electrode with the classification code of E6013 indicates that it has a tensile strength of approximately 60,000 pounds per square inch (psi) and can be used in all positions. The last digit in the code indicates the electrode size – in this case, 1/8 inch or 3.2mm.

By understanding the classification system, buyers can accurately identify the desired electrode size and corresponding properties. Welding suppliers and manufacturers often provide literature or online resources that explain the different electrode sizes and their applications, making it easier for buyers to select the appropriate size for their specific welding needs.

Price of Welding Electrodes Size

The price of welding electrodes can vary depending on several factors, including the size, brand, and quantity purchased. Generally, larger diameter electrodes tend to be more expensive due to the increased material required to manufacture them.

While cost is an important consideration, it is equally crucial to prioritize quality and performance when selecting welding electrodes. Investing in high-quality electrodes may cost more initially but can result in superior welds, increased productivity, and reduced overall welding costs.

Comparing prices among different suppliers and brands can help buyers find the best value for their specific requirements. It is also essential to consider the reputation and reliability of the supplier, as consistency in electrode quality can greatly impact weld performance.

In conclusion, welding electrode size plays a critical role in the welding process. Choosing the right size is crucial for achieving optimal weld quality, penetration, and deposition rates. By understanding the classification system and considering factors such as material thickness and joint design, buyers can make informed decisions when purchasing welding electrodes. While price is a consideration, it is essential to prioritize quality and performance to achieve superior welds and optimize overall welding costs.