A Comprehensive Guide

Introduction:

Welding electrodes play a crucial role in ensuring the quality and efficacy of welding processes. When it comes to mild steel, choosing the right electrode is of utmost importance to achieve strong and durable welds. This article aims to provide a comprehensive guide on welding electrodes for mild steel, focusing on the aspects of purchasing and pricing.

Discuss Welding Electrodes for Mild Steel:

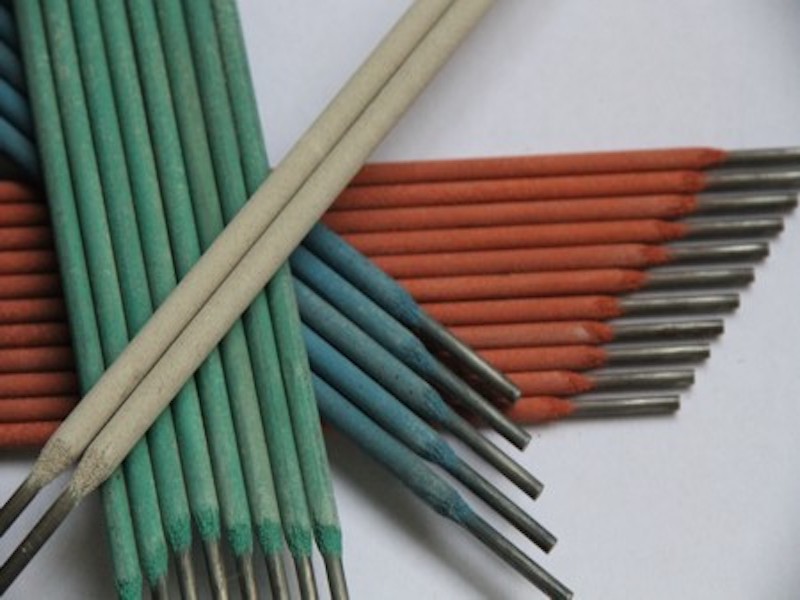

Mild steel is a popular material in various industries due to its excellent strength and weldability. Welding electrodes, also known as welding rods, are consumable tools used in the arc welding process to create a strong bond between metals. These electrodes consist of a metal core surrounded by a flux coating that aids in producing stable arcs and protecting the molten weld metal from atmospheric contamination.

Choosing the right welding electrode for mild steel depends on factors such as the thickness of the steel, welding position, and the required type of joint. An electrode with a mild steel core wire is the most common and widely used choice for welding mild steel. It provides good penetration, high deposition rates, and excellent fusion characteristics. Additionally, mild steel electrodes can be used for a variety of welding techniques, including shielded metal arc welding (SMAW) and gas metal arc welding (GMAW).

Buying Welding Electrodes for Mild Steel:

When buying welding electrodes for mild steel, it is crucial to consider several factors to ensure the desired welding results. The first and foremost consideration is the classification of the electrode. Electrodes are classified based on the American Welding Society (AWS) system, which provides standardization across the industry. Look for electrodes labeled with the AWS E70XX code, where “E” stands for electrode and “70” denotes a tensile strength of 70,000 pounds per square inch.

Another important aspect to consider is the diameter of the electrode. The diameter typically ranges from 1/16″ to 3/32″ for mild steel welding. Thinner electrodes with smaller diameters are suitable for thin sheet metal, while thicker electrodes are better for heavier applications. It is advisable to match the electrode diameter with the thickness of the base metal.

The flux coating on the electrode is also a vital factor, as it determines the electrode’s usability and performance. Different coatings deliver varying characteristics, such as providing better arc stability, reducing spatter, or facilitating easy slag removal. The most common flux coatings for mild steel electrodes include cellulose, rutile, and basic types. Identify the specific requirements of the welding job and select the appropriate coating accordingly.

Price of Welding Electrodes for Mild Steel:

The price of welding electrodes for mild steel can vary depending on several factors, including brand, type, quantity, and retailer. Generally, mild steel welding electrodes are cost-effective, making them accessible to both professional welders and DIY enthusiasts. Prices typically range from $5 to $20 for a pack of five to ten electrodes.

It is important to strike a balance between quality and affordability when purchasing welding electrodes. Be cautious of extremely cheap electrodes, as they may compromise on quality and result in poor welds. Choosing reputable brands with a proven track record ensures that you are investing in electrodes that provide good performance, consistency, and reliability.

Conclusion:

Selecting the right welding electrodes for mild steel is essential to achieve high-quality welds that meet industry standards. By understanding the different factors involved in buying electrodes, including classification, diameter, and flux coating, welders can make informed decisions that ensure optimal results. While price is an important consideration, it should not be the sole determinant when it comes to electrode selection. Investing in reliable and quality electrodes is fundamental to the success of any welding project involving mild steel.