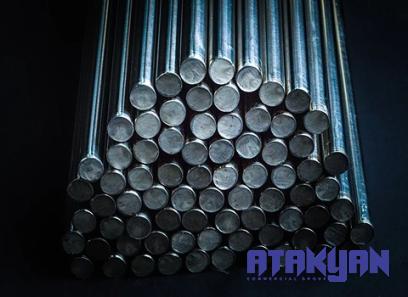

Aluminum welding is an important process in many industries, from aerospace to automotive, construction to manufacturing. One crucial component of aluminum welding is the welding electrode. And when it comes to aluminum welding electrodes, E4047 stands out as a reliable and versatile choice that can greatly improve the quality and efficiency of your welding projects. E4047 is a type of aluminum welding electrode that is specifically designed for welding aluminum alloys, offering excellent results in terms of strength, durability, and overall performance. One of the key advantages of using E4047 electrodes is their ability to create strong and durable welds that can withstand various types of stress and pressure, making them ideal for a wide range of applications.

.

One of the main characteristics of E4047 electrodes is their high silicon content. This high silicon content makes these electrodes suitable for welding aluminum alloys that contain high levels of silicon, such as the popular 4000 series aluminum alloys. The presence of silicon in the electrode helps to improve the fluidity of the molten weld pool, which in turn enhances the overall welding process and results in high-quality welds with excellent mechanical properties.

One of the main characteristics of E4047 electrodes is their high silicon content. This high silicon content makes these electrodes suitable for welding aluminum alloys that contain high levels of silicon, such as the popular 4000 series aluminum alloys. The presence of silicon in the electrode helps to improve the fluidity of the molten weld pool, which in turn enhances the overall welding process and results in high-quality welds with excellent mechanical properties.

..

In addition to their high silicon content, E4047 electrodes also typically contain other alloying elements such as copper, magnesium, and manganese, which further contribute to their strength and performance. These alloying elements work together to improve the weld’s mechanical properties, including its tensile strength, ductility, and resistance to cracking and corrosion, making E4047 electrodes a reliable choice for demanding welding applications. One of the key benefits of using E4047 electrodes for aluminum welding is their versatility. These electrodes can be used for various welding processes, including TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and even oxy-acetylene welding. This versatility makes E4047 electrodes suitable for a wide range of welding applications, from thin sheet metal to thick aluminum components, providing welders with the flexibility they need to tackle different projects with ease. Another advantage of E4047 electrodes is their ease of use. These electrodes are known for their stable arc characteristics and good weldability, which make them suitable for both beginner and experienced welders alike. The stable arc provided by E4047 electrodes helps to ensure smooth and consistent welds, while their good weldability allows for easy control over the welding process, resulting in high-quality welds with minimal defects and rework. When it comes to welding aluminum, one of the main challenges that welders face is the formation of porosity in the welds. Porosity can weaken the weld and reduce its quality, leading to potential defects and failures in the welded part. However, with E4047 electrodes, welders can minimize the risk of porosity thanks to their excellent gas shielding properties. These electrodes produce a stable and protective gas shield during welding, which helps to prevent air and contaminants from entering the weld pool and causing porosity, resulting in high-quality, porosity-free welds. In conclusion, E4047 aluminum welding electrodes are a reliable and versatile choice for welders looking to achieve high-quality and durable welds in aluminum alloys. With their high silicon content, alloying elements, versatility, ease of use, and excellent gas shielding properties, E4047 electrodes offer numerous benefits that can help improve the quality and efficiency of your welding projects. Whether you are working on automotive components, aircraft structures, or architectural elements, E4047 electrodes can meet your welding needs and deliver strong, reliable welds that stand the test of time. Furthermore, E4047 electrodes are known for their excellent heat dissipation properties. This means that they can effectively manage heat during the welding process, preventing overheating and distortion of the base material. This is particularly important when welding aluminum, which has a high thermal conductivity and can easily warp if not welded with care. By using E4047 electrodes, welders can ensure that the heat is distributed evenly throughout the weld, resulting in a smooth and uniform weld bead without causing any distortion to the workpiece.

In addition to their high silicon content, E4047 electrodes also typically contain other alloying elements such as copper, magnesium, and manganese, which further contribute to their strength and performance. These alloying elements work together to improve the weld’s mechanical properties, including its tensile strength, ductility, and resistance to cracking and corrosion, making E4047 electrodes a reliable choice for demanding welding applications. One of the key benefits of using E4047 electrodes for aluminum welding is their versatility. These electrodes can be used for various welding processes, including TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and even oxy-acetylene welding. This versatility makes E4047 electrodes suitable for a wide range of welding applications, from thin sheet metal to thick aluminum components, providing welders with the flexibility they need to tackle different projects with ease. Another advantage of E4047 electrodes is their ease of use. These electrodes are known for their stable arc characteristics and good weldability, which make them suitable for both beginner and experienced welders alike. The stable arc provided by E4047 electrodes helps to ensure smooth and consistent welds, while their good weldability allows for easy control over the welding process, resulting in high-quality welds with minimal defects and rework. When it comes to welding aluminum, one of the main challenges that welders face is the formation of porosity in the welds. Porosity can weaken the weld and reduce its quality, leading to potential defects and failures in the welded part. However, with E4047 electrodes, welders can minimize the risk of porosity thanks to their excellent gas shielding properties. These electrodes produce a stable and protective gas shield during welding, which helps to prevent air and contaminants from entering the weld pool and causing porosity, resulting in high-quality, porosity-free welds. In conclusion, E4047 aluminum welding electrodes are a reliable and versatile choice for welders looking to achieve high-quality and durable welds in aluminum alloys. With their high silicon content, alloying elements, versatility, ease of use, and excellent gas shielding properties, E4047 electrodes offer numerous benefits that can help improve the quality and efficiency of your welding projects. Whether you are working on automotive components, aircraft structures, or architectural elements, E4047 electrodes can meet your welding needs and deliver strong, reliable welds that stand the test of time. Furthermore, E4047 electrodes are known for their excellent heat dissipation properties. This means that they can effectively manage heat during the welding process, preventing overheating and distortion of the base material. This is particularly important when welding aluminum, which has a high thermal conductivity and can easily warp if not welded with care. By using E4047 electrodes, welders can ensure that the heat is distributed evenly throughout the weld, resulting in a smooth and uniform weld bead without causing any distortion to the workpiece.

…

Additionally, E4047 electrodes offer good corrosion resistance properties, making them suitable for welding applications where the final weld needs to withstand harsh environments or exposure to corrosive elements. The alloying elements in E4047 electrodes help to enhance the weld’s resistance to corrosion, ensuring that the welded part remains strong and durable over time. This is especially important in industries such as marine, offshore, and chemical processing, where components are exposed to corrosive substances on a regular basis. When it comes to strength and durability, E4047 electrodes do not disappoint. These electrodes are designed to create welds with high tensile strength, which is essential for ensuring the structural integrity of welded assemblies. Whether you are working on load-bearing structures, machinery components, or pressure vessels, E4047 electrodes can provide the strength and reliability needed to meet the demanding requirements of your application. Additionally, the welds produced with E4047 electrodes exhibit good fatigue resistance, contributing to the long-term performance and reliability of the welded part. Another key advantage of E4047 electrodes is their cost-effectiveness. While quality aluminum welding electrodes may have a higher upfront cost compared to standard electrodes, the superior performance and durability of E4047 electrodes can lead to long-term savings by reducing the need for rework, repairs, and replacements. By investing in high-quality electrodes like E4047, welders can achieve better weld quality, increased productivity, and ultimately lower overall project costs in the long run. In conclusion, E4047 aluminum welding electrodes offer a wide range of benefits that make them an excellent choice for welders working with aluminum alloys. From their high silicon content to their versatility, ease of use, gas shielding properties, heat dissipation capabilities, corrosion resistance, strength, durability, and cost-effectiveness, E4047 electrodes provide all the necessary features to ensure successful and reliable welding outcomes. Whether you are a professional welder, a hobbyist, or a manufacturer looking to improve your welding processes, E4047 electrodes are a valuable tool that can help you achieve high-quality welds and meet your project requirements with confidence.

Additionally, E4047 electrodes offer good corrosion resistance properties, making them suitable for welding applications where the final weld needs to withstand harsh environments or exposure to corrosive elements. The alloying elements in E4047 electrodes help to enhance the weld’s resistance to corrosion, ensuring that the welded part remains strong and durable over time. This is especially important in industries such as marine, offshore, and chemical processing, where components are exposed to corrosive substances on a regular basis. When it comes to strength and durability, E4047 electrodes do not disappoint. These electrodes are designed to create welds with high tensile strength, which is essential for ensuring the structural integrity of welded assemblies. Whether you are working on load-bearing structures, machinery components, or pressure vessels, E4047 electrodes can provide the strength and reliability needed to meet the demanding requirements of your application. Additionally, the welds produced with E4047 electrodes exhibit good fatigue resistance, contributing to the long-term performance and reliability of the welded part. Another key advantage of E4047 electrodes is their cost-effectiveness. While quality aluminum welding electrodes may have a higher upfront cost compared to standard electrodes, the superior performance and durability of E4047 electrodes can lead to long-term savings by reducing the need for rework, repairs, and replacements. By investing in high-quality electrodes like E4047, welders can achieve better weld quality, increased productivity, and ultimately lower overall project costs in the long run. In conclusion, E4047 aluminum welding electrodes offer a wide range of benefits that make them an excellent choice for welders working with aluminum alloys. From their high silicon content to their versatility, ease of use, gas shielding properties, heat dissipation capabilities, corrosion resistance, strength, durability, and cost-effectiveness, E4047 electrodes provide all the necessary features to ensure successful and reliable welding outcomes. Whether you are a professional welder, a hobbyist, or a manufacturer looking to improve your welding processes, E4047 electrodes are a valuable tool that can help you achieve high-quality welds and meet your project requirements with confidence.

Your comment submitted.