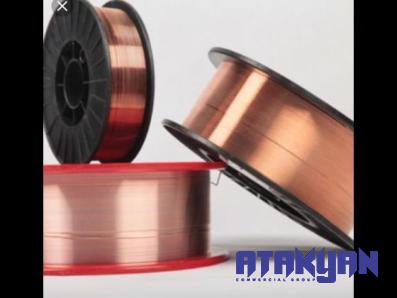

One of the primary reasons why O2 welding tanks are so popular is their versatility. These tanks can be used with various fuel gases, such as acetylene, propane, and propylene, allowing welders to work with a wide range of materials and thicknesses. The high-temperature flame produced by the combination of oxygen and a fuel gas makes it possible to cut through thick metals with ease, making O2 welding tanks a valuable tool for a variety of welding applications. Another significant advantage of O2 welding tanks is their portability. These tanks come in a range of sizes, from small portable tanks to large industrial tanks, allowing welders to choose the right size for their specific needs. Whether you’re working on a small project in your garage or a large-scale industrial job, there’s an O2 welding tank size that’s perfect for the job. The portability of these tanks makes them ideal for on-the-go welding jobs, giving welders the flexibility to work in a variety of environments.

.

One of the key benefits of O2 welding tanks is their reliability. Unlike disposable gas cylinders that can run out of gas unexpectedly, O2 welding tanks can be refilled as needed, ensuring that you always have a steady supply of oxygen on hand for your welding projects. This reliability means that you can work efficiently without having to worry about interruptions or delays due to running out of gas. Another advantage of O2 welding tanks is their environmental friendliness. By using refillable O2 welding tanks instead of disposable gas cylinders, you can significantly reduce waste and minimize your overall environmental impact. Refillable tanks help to decrease the carbon footprint associated with welding projects by eliminating the need to continuously purchase and dispose of single-use cylinders. Choosing O2 welding tanks is a sustainable choice that benefits both your wallet and the environment.

One of the key benefits of O2 welding tanks is their reliability. Unlike disposable gas cylinders that can run out of gas unexpectedly, O2 welding tanks can be refilled as needed, ensuring that you always have a steady supply of oxygen on hand for your welding projects. This reliability means that you can work efficiently without having to worry about interruptions or delays due to running out of gas. Another advantage of O2 welding tanks is their environmental friendliness. By using refillable O2 welding tanks instead of disposable gas cylinders, you can significantly reduce waste and minimize your overall environmental impact. Refillable tanks help to decrease the carbon footprint associated with welding projects by eliminating the need to continuously purchase and dispose of single-use cylinders. Choosing O2 welding tanks is a sustainable choice that benefits both your wallet and the environment.

..

Additionally, O2 welding tanks are compatible with a wide range of cutting and welding torches, making them a versatile choice for welders who use multiple torch types in their work. Whether you prefer a traditional cutting torch, a plasma cutter, or a specialized welding torch, O2 welding tanks can accommodate your preferred equipment, allowing you to work with the tools you’re most comfortable using. This compatibility ensures that you can achieve optimal performance with your existing welding setup, without the need for costly equipment upgrades or replacements. When it comes to durability, O2 welding tanks are built to withstand the rigors of the welding environment. Constructed from robust materials and designed to meet industry standards for safety and performance, O2 welding tanks are built to last through years of heavy use. Whether you’re working in a workshop, a construction site, or a manufacturing facility, you can rely on your O2 welding tank to deliver consistent and reliable performance, project after project.

Additionally, O2 welding tanks are compatible with a wide range of cutting and welding torches, making them a versatile choice for welders who use multiple torch types in their work. Whether you prefer a traditional cutting torch, a plasma cutter, or a specialized welding torch, O2 welding tanks can accommodate your preferred equipment, allowing you to work with the tools you’re most comfortable using. This compatibility ensures that you can achieve optimal performance with your existing welding setup, without the need for costly equipment upgrades or replacements. When it comes to durability, O2 welding tanks are built to withstand the rigors of the welding environment. Constructed from robust materials and designed to meet industry standards for safety and performance, O2 welding tanks are built to last through years of heavy use. Whether you’re working in a workshop, a construction site, or a manufacturing facility, you can rely on your O2 welding tank to deliver consistent and reliable performance, project after project.

…

In conclusion, O2 welding tanks are an essential tool for welders who demand versatility, portability, cost-effectiveness, and safety in their welding equipment. With their reliability, environmental friendliness, precision control, compatibility with a range of torches, and durability, O2 welding tanks offer a host of benefits that make them a smart choice for any welding professional or hobbyist. Invest in an O2 welding tank today and experience the convenience, efficiency, and quality that these tanks bring to your welding projects. Whether you’re cutting, welding, brazing, or heating, an O2 welding tank is the key to achieving outstanding results in your welding work.

In conclusion, O2 welding tanks are an essential tool for welders who demand versatility, portability, cost-effectiveness, and safety in their welding equipment. With their reliability, environmental friendliness, precision control, compatibility with a range of torches, and durability, O2 welding tanks offer a host of benefits that make them a smart choice for any welding professional or hobbyist. Invest in an O2 welding tank today and experience the convenience, efficiency, and quality that these tanks bring to your welding projects. Whether you’re cutting, welding, brazing, or heating, an O2 welding tank is the key to achieving outstanding results in your welding work.

Your comment submitted.