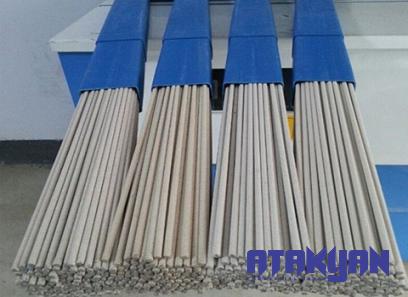

Aluminum welding can be a challenging process, but with the right tools and techniques, it is possible to create strong and durable welds on aluminum materials. One of the key components in aluminum welding is the use of aluminum welding electrodes. These electrodes are essential in the welding process as they provide the heat and filler material necessary to bond aluminum pieces together. Aluminum welding electrodes come in various types and compositions, each suited for specific applications and welding processes. Understanding the different types of aluminum welding electrodes available can help you choose the right one for your welding needs.

.

When using aluminum welding electrodes, it is important to follow best practices to ensure a successful welding process. Proper cleaning and preparation of the aluminum surfaces to be welded are crucial for achieving clean and strong welds. Aluminum oxide, which forms naturally on the surface of aluminum, must be removed before welding to prevent contamination and ensure proper fusion of the materials. Additionally, selecting the appropriate welding technique and settings for the specific electrode being used is essential for achieving the desired weld quality. Whether you are using TIG or MIG welding processes, adjusting the welding parameters such as current, voltage, and travel speed can greatly impact the final weld outcome.

When using aluminum welding electrodes, it is important to follow best practices to ensure a successful welding process. Proper cleaning and preparation of the aluminum surfaces to be welded are crucial for achieving clean and strong welds. Aluminum oxide, which forms naturally on the surface of aluminum, must be removed before welding to prevent contamination and ensure proper fusion of the materials. Additionally, selecting the appropriate welding technique and settings for the specific electrode being used is essential for achieving the desired weld quality. Whether you are using TIG or MIG welding processes, adjusting the welding parameters such as current, voltage, and travel speed can greatly impact the final weld outcome.

..

Proper preparation and cleanliness of the welding surfaces are paramount when working with aluminum materials. Removing aluminum oxide and other contaminants from the surfaces to be welded is essential for ensuring proper fusion and creating strong weld joints. Investing time in preparing the welding surfaces can greatly improve the overall quality of your welds. When it comes to welding techniques and settings, experimentation and practice play a key role in mastering the art of aluminum welding. Adjusting welding parameters such as current, voltage, and travel speed to match the specific electrode being used can help you achieve optimal weld performance and consistency. When purchasing aluminum welding electrodes, it is important to source your materials from reputable suppliers that prioritize quality and reliability. High-quality electrodes can make a significant difference in the success of your welding projects, offering superior performance and consistent results.

Proper preparation and cleanliness of the welding surfaces are paramount when working with aluminum materials. Removing aluminum oxide and other contaminants from the surfaces to be welded is essential for ensuring proper fusion and creating strong weld joints. Investing time in preparing the welding surfaces can greatly improve the overall quality of your welds. When it comes to welding techniques and settings, experimentation and practice play a key role in mastering the art of aluminum welding. Adjusting welding parameters such as current, voltage, and travel speed to match the specific electrode being used can help you achieve optimal weld performance and consistency. When purchasing aluminum welding electrodes, it is important to source your materials from reputable suppliers that prioritize quality and reliability. High-quality electrodes can make a significant difference in the success of your welding projects, offering superior performance and consistent results.

…

In conclusion, aluminum welding electrodes are indispensable tools for welders looking to create strong and durable welds on aluminum materials. By understanding the different types of electrodes available, selecting the appropriate electrode for your specific application, and following best practices in the welding process, you can elevate your aluminum welding skills to new heights. Embrace the versatility and potential of aluminum welding electrodes, and embark on a journey from zero to one hundred in mastering the art of aluminum welding.

In conclusion, aluminum welding electrodes are indispensable tools for welders looking to create strong and durable welds on aluminum materials. By understanding the different types of electrodes available, selecting the appropriate electrode for your specific application, and following best practices in the welding process, you can elevate your aluminum welding skills to new heights. Embrace the versatility and potential of aluminum welding electrodes, and embark on a journey from zero to one hundred in mastering the art of aluminum welding.

Your comment submitted.