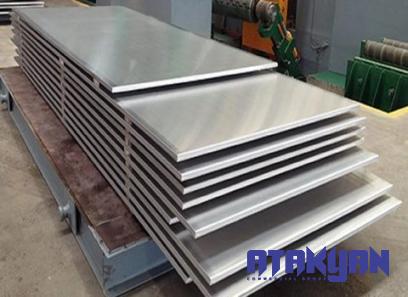

Stainless steel is a versatile material that finds applications across numerous industries due to its durability, resistance to corrosion, and strength. When it comes to high-quality stainless steel electrodes, 316L stainless steel electrodes are a popular choice for various welding tasks. In this comprehensive guide, we will explore everything you need to know about 316L stainless steel electrodes and how you can make an informed decision when buying them. Let’s start by understanding what 316L stainless steel electrodes are and why they are a preferred choice for many welding applications. 316L stainless steel is a low-carbon variant of 316 steel, which contains molybdenum that enhances its corrosion resistance. The ‘L’ in 316L stands for low carbon, making it less susceptible to sensitization – a process that can lead to intergranular corrosion in stainless steel.

.

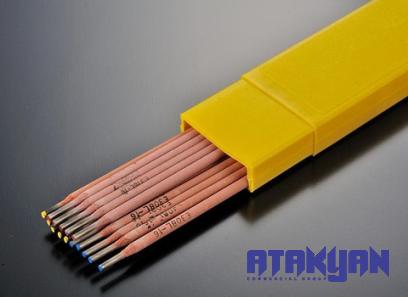

When it comes to purchasing 316L stainless steel electrodes, there are a few key tips to keep in mind to ensure you are getting the right product for your needs. Firstly, make sure to select electrodes from reputable manufacturers or suppliers known for their high-quality welding products. This will help ensure the consistency and reliability of the electrodes, leading to better welding performance and results. It is also important to consider the specific welding requirements of your project when choosing 316L stainless steel electrodes. Factors such as the material thickness, welding position, and desired weld characteristics will influence the type and size of electrodes you should use. Consulting with welding experts or professionals can help you determine the most suitable electrodes for your application. Another essential aspect to consider when buying 316L stainless steel electrodes is their packaging and storage. Proper storage of electrodes is crucial to maintaining their integrity and performance. Ensure that the electrodes are stored in a dry and temperature-controlled environment to prevent moisture absorption and potential contamination. Additionally, check the expiry date on the packaging to ensure the electrodes are within their shelf life for optimal performance.

When it comes to purchasing 316L stainless steel electrodes, there are a few key tips to keep in mind to ensure you are getting the right product for your needs. Firstly, make sure to select electrodes from reputable manufacturers or suppliers known for their high-quality welding products. This will help ensure the consistency and reliability of the electrodes, leading to better welding performance and results. It is also important to consider the specific welding requirements of your project when choosing 316L stainless steel electrodes. Factors such as the material thickness, welding position, and desired weld characteristics will influence the type and size of electrodes you should use. Consulting with welding experts or professionals can help you determine the most suitable electrodes for your application. Another essential aspect to consider when buying 316L stainless steel electrodes is their packaging and storage. Proper storage of electrodes is crucial to maintaining their integrity and performance. Ensure that the electrodes are stored in a dry and temperature-controlled environment to prevent moisture absorption and potential contamination. Additionally, check the expiry date on the packaging to ensure the electrodes are within their shelf life for optimal performance.

..

Furthermore, safety is paramount when working with welding electrodes, especially when welding stainless steel. Make sure to adhere to safety guidelines and wear appropriate personal protective equipment, such as welding gloves, helmet, and protective clothing, to protect yourself from potential hazards. Additionally, ensure proper ventilation in the work area to prevent exposure to harmful fumes and gases generated during welding. By mastering the art of selecting and using 316L stainless steel electrodes, you can elevate your welding capabilities and tackle a wide range of projects with confidence. Whether you are working on stainless steel fabrications, pipeline installations, or structural welding, having the right electrodes at your disposal can make a significant difference in the quality and durability of your welds.

Furthermore, safety is paramount when working with welding electrodes, especially when welding stainless steel. Make sure to adhere to safety guidelines and wear appropriate personal protective equipment, such as welding gloves, helmet, and protective clothing, to protect yourself from potential hazards. Additionally, ensure proper ventilation in the work area to prevent exposure to harmful fumes and gases generated during welding. By mastering the art of selecting and using 316L stainless steel electrodes, you can elevate your welding capabilities and tackle a wide range of projects with confidence. Whether you are working on stainless steel fabrications, pipeline installations, or structural welding, having the right electrodes at your disposal can make a significant difference in the quality and durability of your welds.

…

In conclusion, 316L stainless steel electrodes are a valuable asset for welders looking to achieve strong, corrosion-resistant welds on 316 and 316L stainless steels. By understanding the unique properties of these electrodes, choosing the right product for your welding needs, and implementing proper welding techniques, you can take your welding skills to the next level and produce high-quality welds with ease. Make an informed decision when buying 316L stainless steel electrodes, invest in your welding skills, and unlock the potential to create exceptional welds that stand the test of time. Embrace the versatility and reliability of 316L stainless steel electrodes in your welding projects, and experience the satisfaction of producing professional-grade welds that exceed expectations.

In conclusion, 316L stainless steel electrodes are a valuable asset for welders looking to achieve strong, corrosion-resistant welds on 316 and 316L stainless steels. By understanding the unique properties of these electrodes, choosing the right product for your welding needs, and implementing proper welding techniques, you can take your welding skills to the next level and produce high-quality welds with ease. Make an informed decision when buying 316L stainless steel electrodes, invest in your welding skills, and unlock the potential to create exceptional welds that stand the test of time. Embrace the versatility and reliability of 316L stainless steel electrodes in your welding projects, and experience the satisfaction of producing professional-grade welds that exceed expectations.

Your comment submitted.