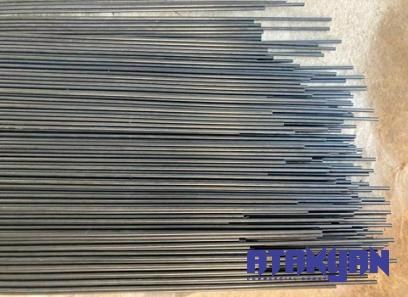

Welding is a crucial process in various industries, from construction to manufacturing. It involves joining two pieces of metal using heat to melt the materials and a filler material to create a strong bond. One of the key components in welding is the welding electrode, a consumable electrode used to deliver the electric current needed to create an arc between the electrode and the base material. Among the various types of welding electrodes available, the e6013 welding electrode stands out as a popular and versatile choice for both professional welders and DIY enthusiasts. The e6013 welding electrode is a mild-steel, all-position, rutile-coated electrode that is renowned for its ease of use and versatility. It is suitable for welding a wide range of mild steels and low-alloy steels, making it a versatile option for various welding applications. The “e” in e6013 denotes that it is an electrode, while the “60” signifies a tensile strength of 60,000 psi, and the “13” indicates it can be run in all positions (flat, horizontal, vertical, overhead). The rutile coating on the electrode provides excellent arc stability, smooth weld bead appearance, and easy slag removal.

.

One of the defining features of the e6013 welding electrode is its rutile coating, which plays a crucial role in enhancing its welding properties. The rutile coating contains high levels of titanium dioxide, which contributes to the electrode’s excellent arc stability and smooth weld bead appearance. This coating also helps to create a protective gas shield around the weld pool, preventing atmospheric contamination and ensuring clean, sound welds. Additionally, the rutile coating aids in easy slag removal after welding, saving time and effort during the cleanup process. The all-position capability of the e6013 welding electrode makes it versatile and well-suited for various welding scenarios. Whether you need to weld in a flat, horizontal, vertical, or overhead position, the e6013 electrode can adapt to different welding orientations without compromising on weld quality. This flexibility makes it an ideal choice for welders working on projects that require welding in multiple positions, maximizing efficiency and productivity.

One of the defining features of the e6013 welding electrode is its rutile coating, which plays a crucial role in enhancing its welding properties. The rutile coating contains high levels of titanium dioxide, which contributes to the electrode’s excellent arc stability and smooth weld bead appearance. This coating also helps to create a protective gas shield around the weld pool, preventing atmospheric contamination and ensuring clean, sound welds. Additionally, the rutile coating aids in easy slag removal after welding, saving time and effort during the cleanup process. The all-position capability of the e6013 welding electrode makes it versatile and well-suited for various welding scenarios. Whether you need to weld in a flat, horizontal, vertical, or overhead position, the e6013 electrode can adapt to different welding orientations without compromising on weld quality. This flexibility makes it an ideal choice for welders working on projects that require welding in multiple positions, maximizing efficiency and productivity.

..

When it comes to welding speed and productivity, the e6013 welding electrode shines due to its high deposition efficiency. The electrode’s ability to deposit a significant amount of weld metal per unit length results in faster welding speeds and increased productivity. Whether you are working on a large-scale welding project or need to complete multiple welds in a short timeframe, the e6013 electrode’s high deposition efficiency allows you to get the job done quickly and efficiently. Furthermore, the e6013 welding electrode excels in welding on dirty, rusted, or painted surfaces, thanks to its strong arc force and deep penetration capabilities. Even in challenging welding conditions where surface preparation may be limited, the e6013 electrode can create strong, quality welds with minimal spatter and distortion. Its forgiving nature makes it a reliable choice for welding a variety of materials, including mild steels, low-alloy steels, and galvanized metals, with consistent results.

When it comes to welding speed and productivity, the e6013 welding electrode shines due to its high deposition efficiency. The electrode’s ability to deposit a significant amount of weld metal per unit length results in faster welding speeds and increased productivity. Whether you are working on a large-scale welding project or need to complete multiple welds in a short timeframe, the e6013 electrode’s high deposition efficiency allows you to get the job done quickly and efficiently. Furthermore, the e6013 welding electrode excels in welding on dirty, rusted, or painted surfaces, thanks to its strong arc force and deep penetration capabilities. Even in challenging welding conditions where surface preparation may be limited, the e6013 electrode can create strong, quality welds with minimal spatter and distortion. Its forgiving nature makes it a reliable choice for welding a variety of materials, including mild steels, low-alloy steels, and galvanized metals, with consistent results.

…

In conclusion, the e6013 welding electrode is a versatile, user-friendly, and high-performing welding consumable that delivers excellent results across a wide range of welding applications. Its rutile coating, all-position capability, weld quality, ease of use, deposition efficiency, and adaptability to adverse welding conditions make it a preferred choice for welders seeking a reliable and efficient electrode. Whether you are a novice welder learning the ropes or a seasoned professional tackling complex welding projects, the e6013 electrode is a trusted companion that consistently delivers superior weld performance and craftsmanship.

In conclusion, the e6013 welding electrode is a versatile, user-friendly, and high-performing welding consumable that delivers excellent results across a wide range of welding applications. Its rutile coating, all-position capability, weld quality, ease of use, deposition efficiency, and adaptability to adverse welding conditions make it a preferred choice for welders seeking a reliable and efficient electrode. Whether you are a novice welder learning the ropes or a seasoned professional tackling complex welding projects, the e6013 electrode is a trusted companion that consistently delivers superior weld performance and craftsmanship.

Your comment submitted.