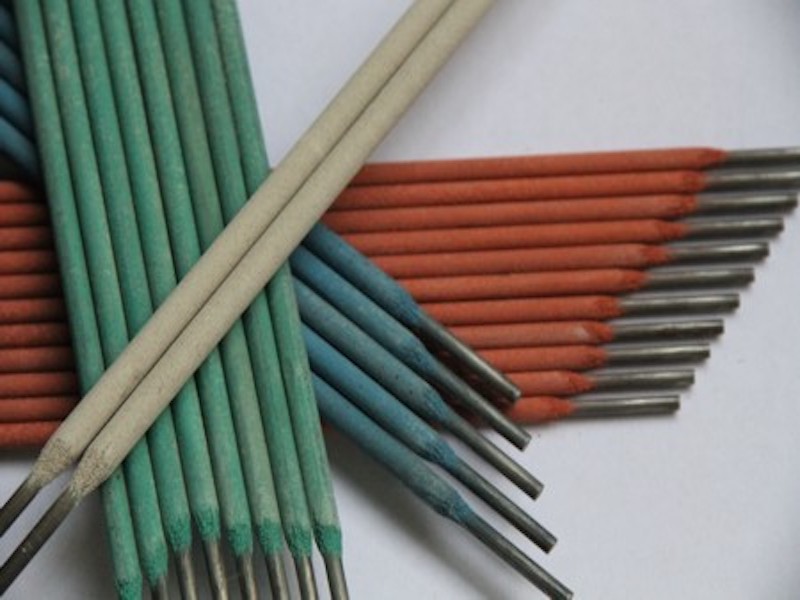

Different Types of Welding Wire

Welding is a critical process in various industries such as automotive, construction, and manufacturing. It involves the joining of two or more metal pieces using heat and pressure. One of the essential components of the welding process is welding wire, which acts as a filler material. Welding wire is available in different types, each designed for specific applications. In this article, we will discuss the different types of welding wire, factors to consider when buying, and the price range of these wires.

1. Discuss different types of welding wire

a. Flux-Core Welding Wire:

Flux-core welding wire, also known as flux-cored arc welding (FCAW) wire, is a type of wire that contains flux in its core. This wire is commonly used in heavy fabrication, construction, shipbuilding, and pipeline welding. Flux-core welding wire offers high deposition rates and deep penetration, making it ideal for welding thick materials. It also produces a shielding gas during the welding process, eliminating the need for an external gas source.

b. Solid Welding Wire:

Solid welding wire, also referred to as gas metal arc welding (GMAW) wire or MIG wire, is the most commonly used type of welding wire. It consists of a solid metal wire without any flux core. Solid welding wire is widely used in automotive, manufacturing, and repair applications. It provides a clean and stable arc, allowing for precise welds with minimal spatter. This type of wire requires an external shielding gas like argon or a mixture of CO2 and argon.

c. Aluminium Welding Wire:

Aluminium welding wire is specifically designed for joining aluminium alloys. It offers excellent corrosion resistance and high strength. Aluminium welding wire is commonly used in the automotive and aerospace industries. It requires a higher level of expertise compared to welding steel, as aluminium has a lower melting point and is more prone to heat distortion. It is typically used with a pure argon shielding gas.

d. Stainless Steel Welding Wire:

Stainless steel welding wire is used for welding various grades of stainless steel. It offers excellent corrosion resistance and high strength, making it suitable for applications that require resistance to harsh environments. Stainless steel welding wire is used in industries such as food processing, chemical, and medical. It is typically used with a shielding gas such as argon or a mixture of CO2 and argon.

2. Buying different types of welding wire

When buying welding wire, several factors need to be considered to ensure you choose the right type for your specific application. These factors include:

a. Material compatibility:

Consider the type of metal you will be welding. Different welding wires are specifically designed for welding specific metals. Ensure the welding wire you choose is compatible with the metal you are working with.

b. Wire diameter:

The diameter of the welding wire determines the current range and metal thickness it can weld. Thicker wires are suitable for heavier applications, while thinner wires are ideal for thinner metals.

c. Shielding gas:

Some welding wires require a specific shielding gas for optimal performance. Consider the availability and cost of the required shielding gas before purchasing the welding wire.

d. Welding position:

Certain welding wires are more suitable for specific welding positions, such as flat, horizontal, vertical, or overhead. Consider the position in which you will be welding and choose a welding wire that is appropriate for that position.

3. Price of different types of welding wire

The price of welding wire varies depending on the type, brand, and quantity. Generally, flux-core welding wire tends to be more expensive compared to solid welding wire due to the flux core component. Aluminium welding wire and stainless steel welding wire also tend to be more expensive than standard steel welding wire due to the higher cost of materials. Additionally, the price can vary based on the wire diameter and the quantity purchased. It is advisable to compare prices from different suppliers to get the best value for your money.

In conclusion, welding wire plays a crucial role in the welding process by acting as a filler material. It is available in different types, including flux-core welding wire, solid welding wire, aluminium welding wire, and stainless steel welding wire. When buying welding wire, factors such as material compatibility, wire diameter, shielding gas, and welding position need to be considered. The price of different types of welding wire varies, so it is advisable to compare prices from different suppliers. By choosing the right type of welding wire, you can ensure precise and strong welds for your applications.