Exploring the Process, Buying Considerations, and Pricing

Introduction:

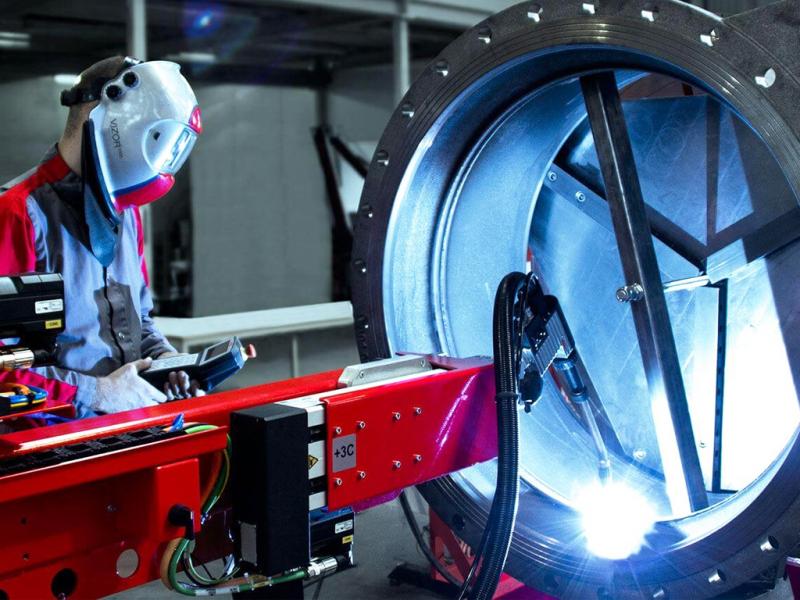

Welding steel to stainless is a process that brings together two distinct materials with varying properties. Whether its industrial fabrication or a DIY project, understanding the intricacies of this welding process is crucial. This article aims to discuss and shed light on welding steel to stainless, providing insights into buying considerations and pricing.

Discussing Welding Steel to Stainless:

Welding steel to stainless involves the fusion of steel and stainless steel, bringing together their mechanical and aesthetic qualities. While both materials exhibit strength, steel is known for its superior durability and affordability, whereas stainless steel boasts excellent corrosion resistance and is prized for its attractive appearance. By joining the two metals through welding, engineers and fabricators can create innovative and robust structures capable of withstanding harsh environments.

Buying Welding Steel to Stainless:

When embarking on a project that requires welding steel to stainless, there are a few factors one should consider before making a purchase. These factors include:

1. Material Selection: Opt for a high-quality steel that matches the strength and composition of the stainless steel being used. Selecting the right grade of steel will ensure a stronger bond and reduce the risk of corrosion at the welded joint.

2. Welding Method: Different welding methods can be used to weld steel to stainless, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Each method has its own advantages, and the selection should be based on the project requirements and the skill level of the welder.

3. Filler Metals: Filler metals play a critical role in welding steel to stainless. They serve as a bridge between the two metals, providing strength and compatibility. It is essential to choose a filler metal that matches the properties of both the steel and stainless steel, ensuring a strong and durable bond.

Price of Welding Steel to Stainless:

The cost of welding steel to stainless is influenced by several factors, including the price of the base materials, the welding method used, and the skill level of the welder. Generally, stainless steel tends to be more expensive than regular steel due to its superior corrosion resistance and aesthetic appeal. However, the overall cost may vary depending on the specific requirements of the project.

In addition to material costs, the skill level of the welder also affects pricing. Projects involving welding steel to stainless require precision and expertise. Therefore, highly skilled welders may command a higher hourly rate, increasing the overall project cost.

Another consideration is the welding method employed. TIG welding, known for its precise and clean welds, is often more expensive than MIG welding. The increased labor and equipment costs associated with TIG welding can influence the final price.

Ultimately, the price of welding steel to stainless should be considered as an investment. The longevity and durability of the welded joint, along with the quality of workmanship, should be the primary focus while evaluating the overall cost.

Conclusion:

Welding steel to stainless offers a wide range of opportunities in construction and fabrication projects. Understanding the welding process, as well as the factors involved in buying and pricing, is essential for a successful outcome. By selecting the right materials, employing the appropriate welding method, and considering the associated costs, welders and fabricators can create strong and durable structures that seamlessly blend the mechanical properties of steel with the aesthetic allure of stainless steel.By mastering the techniques and considerations involved in welding steel to stainless, professionals can deliver high-quality work that meets industry standards and customer expectations.

To further enhance the welding process, there are certain tips and best practices to keep in mind:

1. Cleanliness: Before welding, it is crucial to thoroughly clean both the steel and stainless steel surfaces. Any impurities, such as dirt, oil, or rust, can hinder the welding process and compromise the strength of the joint. Utilize appropriate cleaning methods such as degreasers or solvents to ensure a clean surface.

2. Proper Joint Preparation: When preparing the joint, ensure that it is appropriately designed and fits snugly. The joint should have sufficient weld access and enough space for the filler material. Properly preparing the joint minimizes stress, distortion, and the risk of weld failure.

3. Preheating: Preheating the materials, especially the stainless steel, can be beneficial in preventing cracking and ensuring proper fusion. The preheating temperature depends on the specific grade of stainless steel being used, so consult the guidelines or seek advice from experts.

4. Control Heat Input: The heat input during the welding process should be carefully controlled to prevent excessive heat or cold cracking. Maintaining the proper heat levels ensures the integrity of the weld and minimizes distortion.

5. Back Purging: When welding stainless steel, it is important to consider back purging to prevent oxidation and ensure the weld’s corrosion resistance. Back purging involves using an inert gas, such as argon, to shield the backside of the weld.

6. Post-Weld Treatment: After completion, it is recommended to perform post-weld treatment to alleviate stress and optimize the weld’s mechanical properties. This may involve techniques such as grinding, heat treatment, or stress relief annealing.

In conclusion, welding steel to stainless opens up a world of possibilities for creative design and durable structural components. By understanding the intricacies of the welding process, considering the various factors involved in material selection, and being conscious of pricing, professionals can create successful welds that meet both functional and aesthetic requirements. Together with proper cleaning, joint preparation, and control of heat input, welders can ensure high-quality results that withstand the test of time.