At the heart of every welding process lies a fundamental technique known as basic electrode welding. This method, also commonly referred to as shielded metal arc welding (SMAW), is a versatile and widely-used process in the world of metal fabrication and repair. Whether you’re a seasoned professional or a complete novice to the world of welding, understanding the ins and outs of basic electrode welding is essential for mastering this craft. In this article, we will take you on a comprehensive journey from the very basics to a deep dive into the intricacies of basic electrode welding, paving the way for you to become a confident and skilled welder.

.

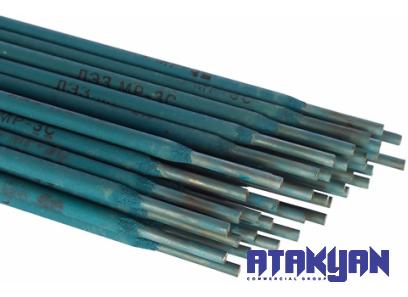

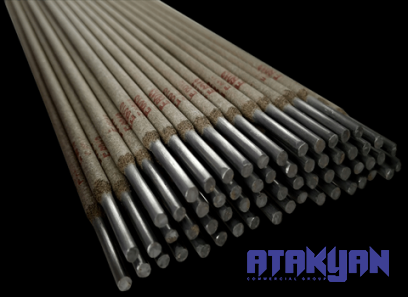

At its core, basic electrode welding involves creating an electric arc between a flux-coated electrode and the workpiece to join two metal components. This process generates intense heat that melts the base metals, allowing them to fuse together when the molten weld pool solidifies. The flux coating on the electrode plays a crucial role in shielding the weld pool from atmospheric contaminants and preventing oxidation, ensuring a strong and clean weld joint. One of the key advantages of basic electrode welding is its simplicity and portability. Unlike more complex welding techniques that require sophisticated equipment, basic electrode welding can be performed using a basic welding machine, a welding electrode, and a power source. This makes it an ideal choice for a wide range of applications, from automotive repair and construction to fabrication projects in remote or outdoor locations.

At its core, basic electrode welding involves creating an electric arc between a flux-coated electrode and the workpiece to join two metal components. This process generates intense heat that melts the base metals, allowing them to fuse together when the molten weld pool solidifies. The flux coating on the electrode plays a crucial role in shielding the weld pool from atmospheric contaminants and preventing oxidation, ensuring a strong and clean weld joint. One of the key advantages of basic electrode welding is its simplicity and portability. Unlike more complex welding techniques that require sophisticated equipment, basic electrode welding can be performed using a basic welding machine, a welding electrode, and a power source. This makes it an ideal choice for a wide range of applications, from automotive repair and construction to fabrication projects in remote or outdoor locations.

Getting Started with Basic Electrode Welding

If you’re new to welding, basic electrode welding is a great entry point to begin your journey. To get started, you’ll need a few essential tools and materials: 1. Welding Machine: A basic AC or DC welding machine capable of generating the required amperage for the electrode you are using. 2. Welding Electrodes: Choose the right type and size of electrode based on the material you are welding and the welding position. 3. Personal Protective Equipment (PPE): Safety should always be a top priority when welding. Invest in a welding helmet, gloves, flame-resistant clothing, and eye protection. 4. Workpiece: The metal components you intend to weld together.

..

Once you have gathered these supplies, you can begin the welding process by following these steps: 1. Prepare the work area by ensuring proper ventilation and securing the workpiece in a stable position. 2. Choose the correct electrode for your welding application and set the welding machine to the recommended amperage. 3. Strike an arc by touching the electrode to the workpiece and quickly withdrawing it to create a spark. This will initiate the welding process. 4. Maintain a steady welding arc length and travel speed to achieve a consistent and uniform weld bead. 5. Move the electrode along the joint, gradually filling the gap with molten metal to create a strong weld.

Once you have gathered these supplies, you can begin the welding process by following these steps: 1. Prepare the work area by ensuring proper ventilation and securing the workpiece in a stable position. 2. Choose the correct electrode for your welding application and set the welding machine to the recommended amperage. 3. Strike an arc by touching the electrode to the workpiece and quickly withdrawing it to create a spark. This will initiate the welding process. 4. Maintain a steady welding arc length and travel speed to achieve a consistent and uniform weld bead. 5. Move the electrode along the joint, gradually filling the gap with molten metal to create a strong weld.

…

Basic electrode welding is more than just a welding technique—it’s a gateway to a world of limitless possibilities, creativity, and growth. As you continue your welding journey, remember to approach each weld with enthusiasm, precision, and a relentless pursuit of excellence. Whether you’re crafting intricate welds on a delicate piece of art or constructing massive steel structures that tower into the sky, your welding skills are a reflection of your dedication, craftsmanship, and passion for the art of welding. So, ignite the arc, embrace the heat, and weld your way to new heights of achievement and fulfillment in the fascinating world of basic electrode welding. Each weld you create is a testament to your craftsmanship, ingenuity, and unwavering commitment to mastering this timeless craft. The world of welding awaits—dive in, explore, and let your welding journey unfold one weld at a time.

Basic electrode welding is more than just a welding technique—it’s a gateway to a world of limitless possibilities, creativity, and growth. As you continue your welding journey, remember to approach each weld with enthusiasm, precision, and a relentless pursuit of excellence. Whether you’re crafting intricate welds on a delicate piece of art or constructing massive steel structures that tower into the sky, your welding skills are a reflection of your dedication, craftsmanship, and passion for the art of welding. So, ignite the arc, embrace the heat, and weld your way to new heights of achievement and fulfillment in the fascinating world of basic electrode welding. Each weld you create is a testament to your craftsmanship, ingenuity, and unwavering commitment to mastering this timeless craft. The world of welding awaits—dive in, explore, and let your welding journey unfold one weld at a time.

Your comment submitted.