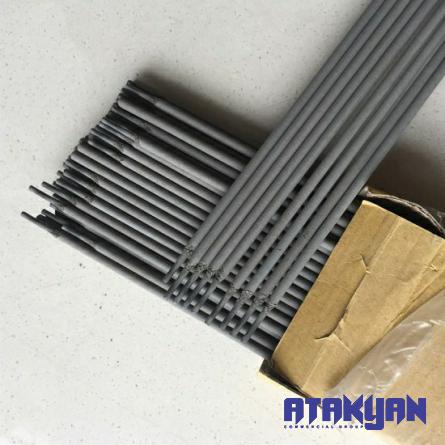

It is done to connect parts by welding electrode 70 13 and by filling the empty space between them. The electrode is a metal wire with a flux coating on it. This type of coating keeps the electric arc constant. The type of welding electrode materials also depends on the use of welding electrodes. When buying electrodes in distribution cemter be sure to note that the packaging contains complete information about the physical characteristics and characteristics related to welding how to maintain etc.

Five Effective Factors for Choosing Welding Electrode.

- The same goes for voltage. He finds 6013 applications in vehicles, shipbuilding, and repair, sheet metal, over-machined mild steel surfaces, and general style construction. 6013 also facilitates a smooth arc that is easily maintained with minimal spray losses. The slag produced by this process rises easily and provides a contour of fine wavy beads. Rapid solidification slag of the electrode offers good performance when welding in low vertical positions. The electrode is widely used for welding clean and new metal sheets. The wire is a mild steel electrode coated with high titanium potassium. This coating helps to produce a spray arc that leads to our deep penetration Yildz wire h polishes are melted on hard metals by welding them. This high-deposition electrode is suitable for low carbon and medium steel. This electrode is a low hydrogen iron powder electrode with outstanding mechanical properties that makes the wire resistant to cracking and helps to create X-ray weld quality. 7018 is capable of delivering uniform welds on metal, and Amazon Services LLC Affiliate Program is an affiliate advertising program designed to provide sites for sites to earn advertising money through ads and links to Amazon.com, Amazon. co. UK or Amazon.ca. Contact temperature due to low elongation. Occasionally, sparks are emitted during welding for the following reasons. This happens if the electrode distance from the work surface is large, the amp is too high, and the correct pole is not selected for welding.

Buying High-Quality Welding Electrode

This is mostly used when the welder needs high levels, This is exactly why the 7018 is used to build ship hulls, pressure vessels, boilers, plumbing, heavy equipment, maintenance, production, or construction. The wire is used for jobs that require low penetration and facilitate a smooth, non-spraying arc. The electrode is more commonly considered a “lethal” rod, the 7018 is also commonly known as low hydrogen or “low-high” rod in the field. A number of hardware stores, field welders, and home enthusiasts often fail to store 7018 rods properly. The electrode is a low-hydrogen rod and requires a moisture-free environment to protect it from flux.

This is mostly used when the welder needs high levels, This is exactly why the 7018 is used to build ship hulls, pressure vessels, boilers, plumbing, heavy equipment, maintenance, production, or construction. The wire is used for jobs that require low penetration and facilitate a smooth, non-spraying arc. The electrode is more commonly considered a “lethal” rod, the 7018 is also commonly known as low hydrogen or “low-high” rod in the field. A number of hardware stores, field welders, and home enthusiasts often fail to store 7018 rods properly. The electrode is a low-hydrogen rod and requires a moisture-free environment to protect it from flux.

Your comment submitted.