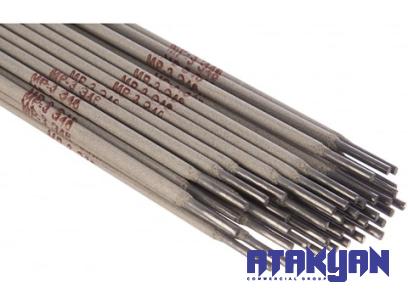

Stainless steel is an alloy known for its exceptional durability, resistance to corrosion, and aesthetic appeal. It is a material that finds a multitude of applications across various industries, from construction to aerospace, automotive to food processing. When it comes to joining stainless steel components together through welding, one of the most reliable and effective methods is stick welding, also known as shielded metal arc welding (SMAW). For this process, the choice of welding electrode is crucial to achieving strong, clean, and precision welds. Among the numerous options available in the market, the E316L-16 Stainless Steel Stick Welding Electrode stands out for its quality, performance, and versatility.

.

The E316L-16 electrode is specifically designed for welding stainless steels of the 316 and 316L types, which are widely used in industries requiring high corrosion resistance. The ‘E’ in its designation indicates that it is an electrode, while ‘316’ denotes the type of stainless steel it is suitable for. The ‘L’ signifies the low carbon content in the electrode, making it ideal for welding applications where minimizing carbon contamination is important to preserve the corrosion resistance of the base metal. The number ’16’ refers to the electrode’s welding position capabilities, with ‘1’ indicating an all-position electrode (also known as a general-purpose electrode) and ‘6’ representing any position, including flat, horizontal, vertical, overhead, and fillet welds.

The E316L-16 electrode is specifically designed for welding stainless steels of the 316 and 316L types, which are widely used in industries requiring high corrosion resistance. The ‘E’ in its designation indicates that it is an electrode, while ‘316’ denotes the type of stainless steel it is suitable for. The ‘L’ signifies the low carbon content in the electrode, making it ideal for welding applications where minimizing carbon contamination is important to preserve the corrosion resistance of the base metal. The number ’16’ refers to the electrode’s welding position capabilities, with ‘1’ indicating an all-position electrode (also known as a general-purpose electrode) and ‘6’ representing any position, including flat, horizontal, vertical, overhead, and fillet welds.

One of the key features that sets the E316L-16 electrode apart is its exceptional welding performance. Whether you are a seasoned professional welder or a hobbyist working on DIY projects, this electrode offers ease of use combined with superior results. Its arc stability, smooth operation, and low spatter production make it suitable for a wide range of welding tasks, from fabricating stainless steel structures to repairing machinery components. The electrode’s ability to produce strong and visually appealing welds with minimal post-weld cleanup ensures efficient and high-quality workmanship.

..

Quality is paramount when it comes to welding consumables, and the E316L-16 electrode meets the highest industry standards for performance and reliability. Compliant with American Welding Society (AWS) specifications, this electrode undergoes rigorous testing and quality control measures to ensure consistent results and customer satisfaction. Welders can trust in the E316L-16 electrode to deliver the performance they need for a wide range of stainless steel welding applications, from small repairs to large-scale fabrications. Apart from its exceptional welding properties, the E316L-16 electrode offers a cost-effective and efficient solution for welders seeking to optimize their welding processes. The electrode’s high deposition rate, excellent weld bead appearance, and low failure rate reduce the need for rework and cleanup, saving time and resources. Its all-position welding capabilities enable welders to work in any orientation, opening up a world of possibilities for tackling challenging welding tasks with ease and precision.

Quality is paramount when it comes to welding consumables, and the E316L-16 electrode meets the highest industry standards for performance and reliability. Compliant with American Welding Society (AWS) specifications, this electrode undergoes rigorous testing and quality control measures to ensure consistent results and customer satisfaction. Welders can trust in the E316L-16 electrode to deliver the performance they need for a wide range of stainless steel welding applications, from small repairs to large-scale fabrications. Apart from its exceptional welding properties, the E316L-16 electrode offers a cost-effective and efficient solution for welders seeking to optimize their welding processes. The electrode’s high deposition rate, excellent weld bead appearance, and low failure rate reduce the need for rework and cleanup, saving time and resources. Its all-position welding capabilities enable welders to work in any orientation, opening up a world of possibilities for tackling challenging welding tasks with ease and precision.

…

In conclusion, the E316L-16 Stainless Steel Stick Welding Electrode is a standout choice for welders who demand excellence in their welding endeavors. With its superior welding performance, reliability, and cost-effectiveness, this electrode empowers welders to achieve professional-quality results with ease and efficiency. From fabricating stainless steel structures to repairing critical machinery components, the E316L-16 electrode is a versatile and dependable ally in the welder’s toolkit. Make the smart choice today and elevate your welding experience with the E316L-16 Stainless Steel Stick Welding Electrode. Join the ranks of skilled welders who trust in the performance and quality of this electrode to deliver exceptional results in stainless steel welding applications. Take your welding capabilities to new heights with the E316L-16 electrode and experience the difference it can make in your welding projects.

In conclusion, the E316L-16 Stainless Steel Stick Welding Electrode is a standout choice for welders who demand excellence in their welding endeavors. With its superior welding performance, reliability, and cost-effectiveness, this electrode empowers welders to achieve professional-quality results with ease and efficiency. From fabricating stainless steel structures to repairing critical machinery components, the E316L-16 electrode is a versatile and dependable ally in the welder’s toolkit. Make the smart choice today and elevate your welding experience with the E316L-16 Stainless Steel Stick Welding Electrode. Join the ranks of skilled welders who trust in the performance and quality of this electrode to deliver exceptional results in stainless steel welding applications. Take your welding capabilities to new heights with the E316L-16 electrode and experience the difference it can make in your welding projects.

Your comment submitted.