A Comprehensive Guide for Buyers

Introduction

Weld metal powder is an essential component in the welding industry, used to produce high-quality welds in various applications. This article aims to discuss the importance of weld metal powder, the factors to consider when buying it, and its price range.

Discuss Weld Metal Powder

Weld metal powder plays a vital role in welding processes, enhancing the quality and efficiency of welds. It is typically made up of metallic alloys, such as iron, nickel, or cobalt, which are compressed into a fine powder form. This powder can then be applied to the weld area to improve its mechanical properties, prevent cracking, and enhance corrosion resistance.

Buying Weld Metal Powder

When considering the purchase of weld metal powder, several factors should be taken into account to ensure you choose the right product for your specific welding needs:

1. Materials Compatibility: One of the most crucial aspects to consider is the compatibility of the weld metal powder with the base materials you are working with. Different powder compositions are suitable for specific applications, so it is essential to consult with experts or refer to product specifications to ensure compatibility.

2. Particle Size: The particle size of the weld metal powder affects its deposition efficiency and structural integrity. Finer particles are beneficial for intricate welds, while coarser particles are suitable for larger-scale projects. Consider the nature of your welding job and select a particle size that aligns with your requirements.

3. Alloy Composition: The alloy composition of the weld metal powder determines its mechanical properties, including hardness, strength, and conductivity. It is crucial to evaluate the composition to ensure the desired characteristics are achieved in the final weld.

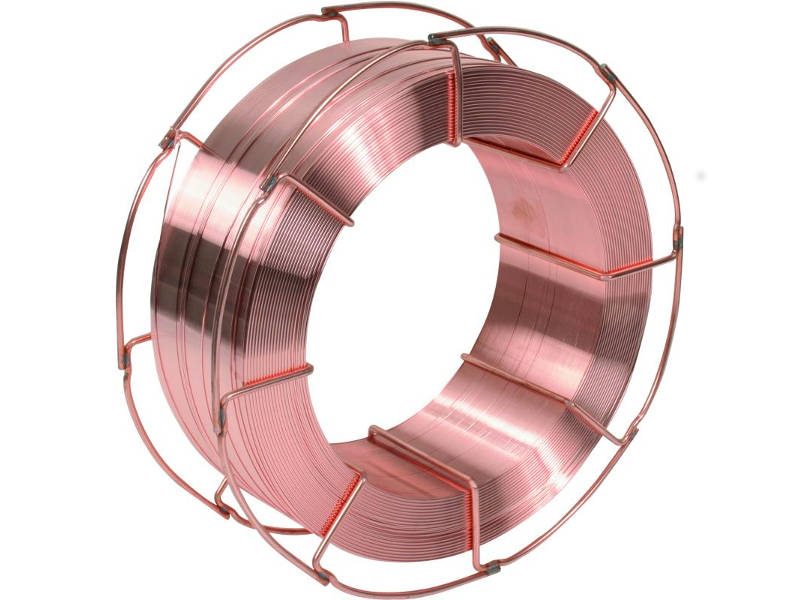

4. Powder Form: Weld metal powder is available in different forms, including cored wire, atomized powder, and agglomerated powder. Each form has its advantages and is suitable for specific welding techniques or equipment. Understand the requirements of your welding process to select the most appropriate powder form.

5. Quality Assurance: To guarantee consistent quality and reliability, opt for reputable manufacturers or suppliers that adhere to stringent quality standards. Consider checking for certifications or accreditations as a testament to the quality of the weld metal powder you are purchasing.

Price of Weld Metal Powder

The price of weld metal powder can vary depending on several factors, including:

1. Powder Composition: Different alloy compositions may have varying costs due to the raw materials used and the manufacturing processes involved. Certain alloys may be more expensive due to their specific properties or scarcity of resources.

2. Quantity: The quantity of weld metal powder you require can impact the price. Purchasing in larger quantities may result in bulk discounts or reduced unit costs. However, be cautious of overstocking, as unused powder may degrade over time.

3. Packaging: The packaging of weld metal powder can also contribute to the overall price. Specialized packaging, such as vacuum-sealed containers or protective coatings, may increase the cost but offer enhanced shelf life and maintain powder integrity.

4. Supplier: The choice of supplier can influence the price of weld metal powder. Reputable suppliers with established market presence might charge slightly higher prices due to their quality assurance and reliability. It is essential to find a balance between price and quality when selecting a supplier.

Conclusion

Weld metal powder is a critical component in welding processes, contributing to the overall quality and durability of welds. When purchasing weld metal powder, it is important to consider factors such as materials compatibility, particle size, alloy composition, powder form, and quality assurance. Additionally, the price of weld metal powder can vary depending on the powder composition, quantity, packaging, and supplier. By carefully evaluating these factors, buyers can select the most suitable weld metal powder for their specific welding applications while ensuring cost-effectiveness.