A Comprehensive Guide for Buyers

Introduction:

Subpowder Co2 welding wire is a popular choice among professionals in the welding industry. This type of wire is widely used for its ease of use, high deposition rates, and superior weld quality. In this article, we will discuss the features and benefits of subpowder Co2 welding wire, as well as provide insights into buying this product and understanding its price.

Discuss Subpowder Co2 Welding Wire:

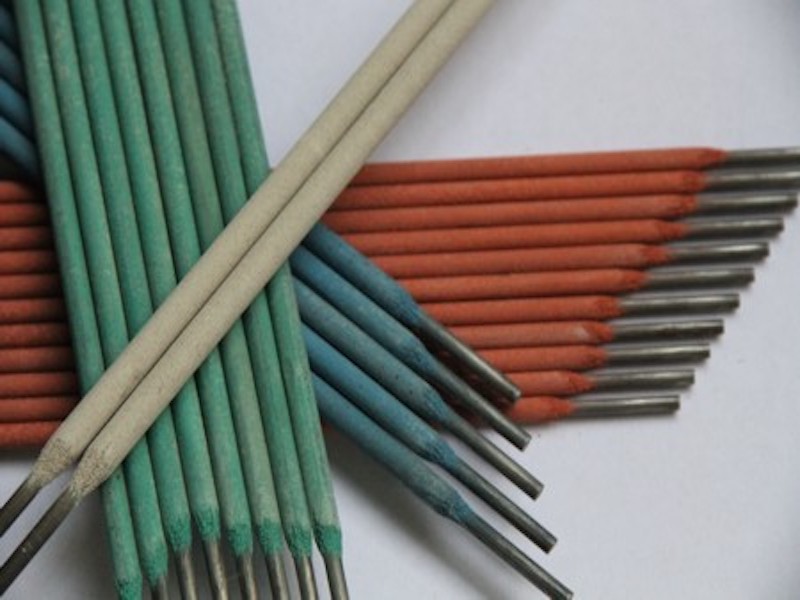

Subpowder Co2 welding wire is a consumable electrode used in the gas metal arc welding (GMAW) process. It consists of a solid steel core surrounded by a powdered flux composition. This flux serves multiple purposes such as shielding the weld from atmospheric contamination, improving arc stability, and enhancing the mechanical properties of the weld.

The subpowder flux composition in Co2 welding wire helps to lower overall costs by reducing the consumption of expensive alloying elements. The presence of flux also improves the efficiency of the welding process, allowing for higher deposition rates compared to solid wire.

One of the key benefits of subpowder Co2 welding wire is its versatility in various applications. It is commonly used for welding carbon steels, low alloy steels, and some stainless steels. This makes it suitable for a wide range of industries, including automotive, construction, and manufacturing.

Buying Subpowder Co2 Welding Wire:

When purchasing subpowder Co2 welding wire, there are several factors to consider to ensure you select the right product for your welding needs.

1. Wire Diameter: Subpowder Co2 welding wire is available in different diameters, typically ranging from 0.8mm to 1.6mm. The choice of wire diameter depends on the thickness of the material being welded and the desired welding current.

2. Wire Grade: Different grades of subpowder Co2 welding wire are available, each designed for specific applications and materials. It is important to select the appropriate wire grade based on the type of steel being welded and the required mechanical properties of the weld.

3. Wire Quality: Ensure that the subpowder Co2 welding wire you purchase meets industry standards and is of high-quality. Look for certifications such as ISO 9001 to ensure the wire’s reliability and performance.

4. Packaging: Consider the packaging options available for subpowder Co2 welding wire. Ideally, the wire should be packaged in a way that protects it from moisture, dust, and other contaminants. Spools or drums with proper labeling and storage instructions are preferred.

Price of Subpowder Co2 Welding Wire:

The price of subpowder Co2 welding wire can vary depending on various factors:

1. Wire Diameter: Thicker wires generally cost more than thinner wires due to the increased material required.

2. Wire Grade: Higher-grade subpowder Co2 welding wire may be more expensive due to the use of premium alloying elements.

3. Packaging: Packaged subpowder Co2 welding wire with added features, such as moisture resistance, may cost slightly more than standard packaging.

4. Quantity: Buying subpowder Co2 welding wire in bulk can often result in discounted prices, making it more cost-effective for large-scale welding operations.

It is important to note that while price is a consideration, the quality of the wire should never be compromised. Cheaper options may result in subpar welds and additional costs from rework or equipment failure.

Conclusion:

Subpowder Co2 welding wire is a versatile and efficient consumable electrode used widely in the welding industry. Its ability to create high-quality welds, cost-effectiveness, and suitability for various applications make it a popular choice among professionals. When buying subpowder Co2 welding wire, consider the wire diameter, grade, quality, packaging, and price. By making an informed purchasing decision, you can ensure optimal welding performance and successful project outcomes.In summary, subpowder Co2 welding wire is a valuable tool in the welding industry. Its unique composition and flux coating provide numerous benefits, including improved weld quality, high deposition rates, and cost-effectiveness. When purchasing subpowder Co2 welding wire, it is crucial to consider factors such as wire diameter, grade, quality, packaging, and price. While price is a consideration, it should not be the sole determining factor, as quality and performance are paramount.

To get the best results, it is recommended to buy subpowder Co2 welding wire from reputable suppliers or manufacturers who meet industry standards and provide high-quality products. Look for certifications such as ISO 9001 to ensure that the wire meets the necessary requirements.

Remember that different applications and materials require specific wire grades, so choose the appropriate grade based on the type of steel being welded and the desired mechanical properties of the weld.

Also, consider the wire diameter, as thicker wires are typically used for heavier materials, while thinner wires are suitable for thinner materials. The wire packaging should protect the wire from moisture, dust, and other contaminants, ensuring its integrity during storage and use.

It’s worth noting that buying subpowder Co2 welding wire in bulk may result in discounted prices, making it more cost-effective for large-scale welding operations. However, it is essential to balance price with quality to avoid any compromise on weld performance.

In conclusion, subpowder Co2 welding wire is a versatile and efficient consumable electrode that offers multiple benefits for welders. Understanding its features, purchasing considerations, and price factors can guide you in selecting the right wire for your welding needs. By choosing a high-quality product that meets your requirements, you can achieve optimal weld results and ensure the success of your welding projects.