A Comprehensive Guide

Introduction:

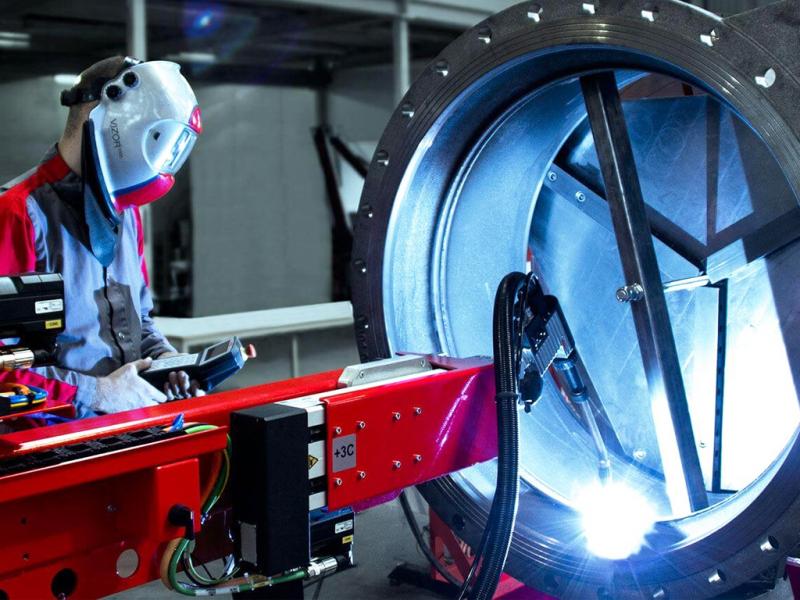

Spot welding is a widely used technique in the manufacturing industry for joining metallic components. One crucial element that contributes to the success of spot welding is the choice of electrode material. In this article, we will delve into the various aspects of spot welding machine electrode material, including buying considerations and pricing factors.

Discuss Spot Welding Machine Electrode Material:

Spot welding machine electrode material plays a vital role in the welding process, as it determines the quality and durability of the weld. The electrode material needs to have excellent thermal and electrical conductivity, high resistance to wear and corrosion, and the ability to withstand high temperatures. Three commonly used types of electrode materials are copper, copper alloys, and refractory metals.

1. Copper Electrodes:

Copper is the most commonly used material for spot welding electrodes due to its exceptional thermal and electrical conductivity. It effectively transfers heat and electricity during the welding process, resulting in efficient welds. Copper electrodes are versatile and can be used for both low and high-volume welding operations. However, they tend to wear out quickly when used on high-strength steel materials.

2. Copper Alloys:

Copper alloys, such as copper-chromium and copper-tungsten, offer improved resistance to wear and corrosion compared to pure copper electrodes. These alloys are more suitable for spot welding applications involving high-strength materials, ensuring a longer electrode lifespan. Copper-chromium alloys possess excellent heat resistance, while copper-tungsten alloys provide enhanced strength and durability.

3. Refractory Metals:

Refractory metals, including molybdenum and tungsten, boast exceptional strength and wear resistance. They are ideal for spot welding applications involving exotic materials, such as stainless steel and nickel alloys. Refractory metal electrodes excel in high-heat applications and carry higher currents efficiently. However, their higher cost and lower electrical conductivity compared to copper can impact their widespread use.

Buying Spot Welding Machine Electrode Material:

When purchasing spot welding machine electrode material, several factors should be considered to ensure optimal performance and value for money.

1. Material Compatibility:

It is crucial to select an electrode material that matches the composition and properties of the workpiece being welded. Different metals require specific electrode materials to achieve the best weld quality and durability. Assessing material compatibility will help prevent issues such as electrode sticking, excessive wear, or poor welds.

2. Electrode Configuration:

The choice of electrode configuration, including shape, size, and contact area, determines the weld quality and achievable welding speeds. The electrode shape should conform to the intended weld joint, ensuring adequate heat concentration and uniform pressure distribution. Optimal electrode size and contact area prevent electrode damage and enhance energy transfer efficiency.

Price of Spot Welding Machine Electrode Material:

The cost of spot welding machine electrode material varies depending on several factors, including the type of material, electrode configuration, and supplier. Generally, copper electrodes are more affordable than copper alloys and refractory metals. Copper-chromium and copper-tungsten alloys are typically priced higher due to their enhanced properties. Refractory metals tend to be the most expensive due to their exceptional strength and wear resistance.

Considering the lifespan and performance characteristics of the electrode material, it is essential to strike a balance between cost and quality. Investing in high-quality electrode material may incur a higher initial expense but can result in reduced downtime, enhanced productivity, and lower long-term costs.

Conclusion:

Spot welding machine electrode material plays a crucial role in ensuring successful and durable welds. Selecting the appropriate material, based on the workpiece properties and welding requirements, can significantly impact the quality and efficiency of spot welding operations. While the cost of electrode material is a factor to consider, prioritizing compatibility and performance can lead to improved welding productivity and overall business profitability.Mastering the nuances of spot welding machine electrode material selection is essential for manufacturers aiming to optimize their welding processes. By considering factors such as material compatibility, electrode configuration, and cost, businesses can ensure high-quality welds and maximize their return on investment.

It is worth noting that while copper electrodes are the most commonly used and cost-effective option, they are not suitable for all welding applications. For instance, when working with high-strength materials, copper alloys or refractory metals may be a better choice due to their superior wear resistance. Manufacturers should assess their specific welding needs and consult with experts or suppliers to determine the most suitable electrode material for their operations.

Another critical consideration when buying spot welding machine electrode material is the reputation and reliability of the supplier. It is advisable to source materials from reputable suppliers that offer consistent quality and provide technical support. Suppliers with a strong track record in the industry can ensure that businesses receive reliable, durable, and high-performance electrode materials.

Additionally, manufacturers should not overlook the importance of electrode maintenance and replacement. Even the highest-quality electrode material will degrade over time due to wear and tear, necessitating periodic replacement. Regular maintenance routines, such as cleaning, polishing, and re-dressing electrodes, can help extend their lifespan and optimize performance.

To summarize, spot welding machine electrode material is a critical component that directly affects the quality and efficiency of spot welding operations. Manufacturers should carefully evaluate their welding needs, consider factors such as material compatibility and electrode configuration, and weigh the cost against the expected performance. By making informed decisions about electrode material selection, businesses can achieve impeccable welds, reduce downtime, and improve overall productivity.