A Comprehensive Guide

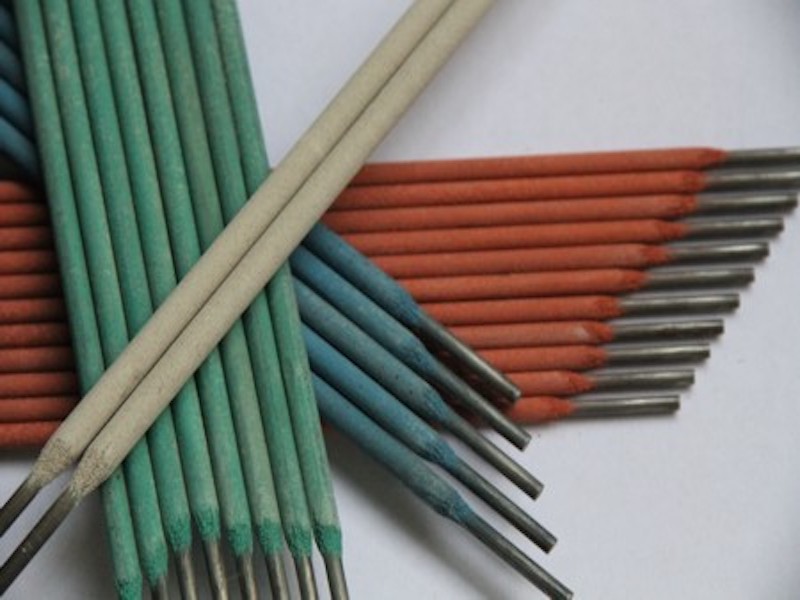

Welding is a process that involves joining two or more pieces of metal together using heat. One essential component of welding is the use of electrodes. Electrodes are vital in this process as they serve as a conductor and provide the necessary heat to melt the metals being joined. In this article, we will delve into the different types of electrodes used in welding, where to buy them, and their price range.

Discuss Electrodes Used in Welding

Electrodes in welding come in various types to suit different welding techniques and applications. The type of electrode used depends on the material being welded, the welding position, and the desired outcome of the weld joint.

One common type of electrode used in welding is the shielded metal arc welding (SMAW) electrode, also known as the stick electrode. SMAW electrodes are coated with a mixture of flux and metal powders, which when heated, creates a gas shield to protect the welding pool from atmospheric contamination.

Another type of electrode commonly used is the gas metal arc welding (GMAW) electrode. GMAW electrodes, also referred to as MIG (metal inert gas) or MAG (metal active gas), are wire electrodes that are continuously fed into the welding arc. A shielding gas, such as argon or a mixture of argon and carbon dioxide, is used to protect the weld pool from oxidation.

For more specialized applications, tungsten inert gas (TIG) electrodes are used. TIG electrodes, made of pure tungsten or a tungsten alloy, have no coating. They are primarily used for welding non-ferrous metals like aluminum, copper, and stainless steel. The use of a separate filler material is necessary in TIG welding.

Buying Electrodes Used in Welding

When it comes to purchasing electrodes used in welding, there are several avenues to explore. One option is to visit local welding supply stores or hardware stores that offer welding supplies. These establishments often have a wide range of electrodes available, catering to different welding processes and applications.

Online retailers are another convenient option for purchasing electrodes. Many specialized welding supply websites offer a comprehensive selection of electrodes, and ordering online provides the convenience of doorstep delivery. Additionally, online retailers often provide detailed product descriptions, making it easier for customers to choose the right electrodes for their specific welding needs.

Before making a purchase, it is important to consider the requirements of the welding project. Factors such as the type of metal being welded, the thickness of the material, and the welding technique being employed should be taken into account. Consulting with knowledgeable staff or researching online can help ensure that the appropriate electrodes are chosen.

Price of Electrodes Used in Welding

The price of electrodes used in welding varies based on factors such as electrode type, brand, and quantity. Generally, SMAW electrodes tend to be more affordable compared to GMAW and TIG electrodes.

SMAW electrodes are commonly sold in packs containing multiple rods. The price range for a multi-pack of SMAW electrodes can start from as low as $10 and go up to $50, depending on the quantity and quality of the electrodes. Higher-quality electrodes often come at a higher price but offer better performance and durability.

GMAW electrodes, on the other hand, are typically sold by weight. The price per pound can range from $5 to $20, depending on the electrode’s composition and quality. It is worth noting that GMAW electrodes require a continuous feed system, which adds an additional cost for equipment.

TIG electrodes can also be purchased by weight, usually in ten-packs or 1-pound increments. The price per pound for TIG electrodes can range from $20 to $100, depending on the material and composition of the electrode. Specialized alloys and rare metals tend to be more expensive.

In conclusion, electrodes play a crucial role in the welding process. Understanding the different types available and their specific applications is necessary for achieving successful welds. When purchasing electrodes, it is important to consider the project requirements and explore different buying options to find the best quality and price. With the right electrodes, welders can produce strong, durable, and aesthetically pleasing weld joints.