A Comprehensive Guide

Introduction:

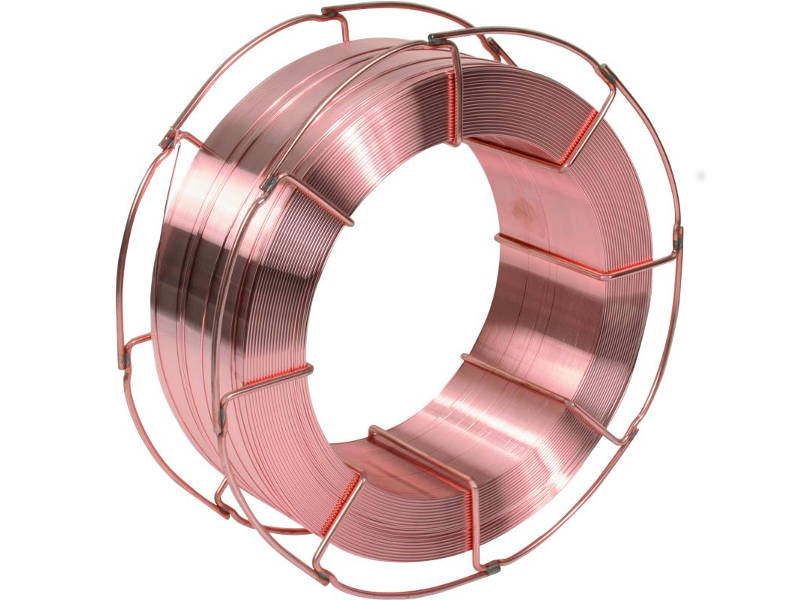

Welding wire flux core is a crucial component in the welding process. It is widely used across various industries due to its exceptional performance and cost-effectiveness. In this article, we will discuss what welding wire flux core is, factors to consider when buying it, and the price range for this essential welding material.

Discuss welding wire flux core:

Welding wire flux core, also known as flux-cored arc welding (FCAW) wire, is a type of electrode that contains a flux material within its core. This flux material has a dual purpose: it creates a shielding gas to protect the weld pool, and it also acts as a deoxidizer, removing impurities from the metal during the welding process.

Flux core wires are classified into two main types: self-shielded and gas-shielded. Self-shielded wires have a flux compound that generates its own shielding gas when it burns, eliminating the need for an external gas supply. On the other hand, gas-shielded wires require an external shielding gas, usually a mixture of carbon dioxide (CO2) and argon (Ar), to protect the weld during the process.

Compared to solid wires used in metal inert gas (MIG) welding, flux core wires offer several advantages. Flux core wires excel in outdoor applications where wind or drafts can adversely affect the shielding gas provided by solid wires. Additionally, flux core wires have higher deposition rates, allowing for faster welding speeds and increased productivity.

Buying welding wire flux core:

When buying welding wire flux core, there are several factors to consider to ensure you choose the right type for your welding needs:

1. Material compatibility: Different flux core wires are designed for specific types of base metals. Ensure that the wire you select is compatible with the material you intend to weld. Common base metals include stainless steel, mild steel, and aluminum.

2. Wire diameter: Flux core wires come in various diameters, typically ranging from 0.030 to 0.045 inches. Thinner wires are suitable for thinner materials, while thicker wires are better suited for welding heavier plate thicknesses. Consider the thickness of the materials you commonly work with when selecting the appropriate wire diameter.

3. Gas or self-shielded: Determine whether your application requires a gas-shielded or self-shielded wire. Self-shielded wires are often preferred for outdoor welding or situations where gas cylinders are impractical. However, gas-shielded wires tend to provide cleaner welds with less spattering.

4. Flux composition: Flux core wires have different flux compositions, and each offers unique characteristics. Some fluxes provide excellent penetration, while others are more forgiving and easier to use, making them ideal for beginners.

Price of welding wire flux core:

The price range for welding wire flux core depends on various factors, including the brand, wire diameter, and quantity purchased. Typically, flux core wires are sold in spools of different sizes, ranging from 1 lb to 33 lbs.

On average, expect to spend between $10 to $80 for a 1 lb spool of welding wire flux core, depending on the diameter and brand. Larger spools, such as the 33 lb ones, can cost anywhere from $30 to $300.

While price is an important consideration, it is equally important to prioritize quality when purchasing your welding wire flux core. Cheaper options may often compromise on performance and reliability, resulting in inferior welds and potential rework. It is advisable to choose reputable brands and invest in high-quality welding wires that suit your specific application.

Conclusion:

Welding wire flux core is an essential component in the welding process, offering numerous advantages over other welding techniques. When purchasing welding wire flux core, consider factors such as material compatibility, wire diameter, and flux composition to ensure optimal performance. While price is a consideration, prioritize quality for reliable, efficient, and superior welds that meet industry standards. Remember, selecting the right welding wire flux core can significantly contribute to the success of your welding projects.