Exploring the Different Types of Welding Rods for Your Projects

Introduction:

Welding rods are an essential component of any welding process. They are the filler material used to join two or more pieces of metal together through the application of heat. Choosing the right type of welding rod can greatly impact the success and quality of the weld. In this article, we will discuss the various types of welding rods available in the market, factors to consider when buying them, and the price ranges you can expect.

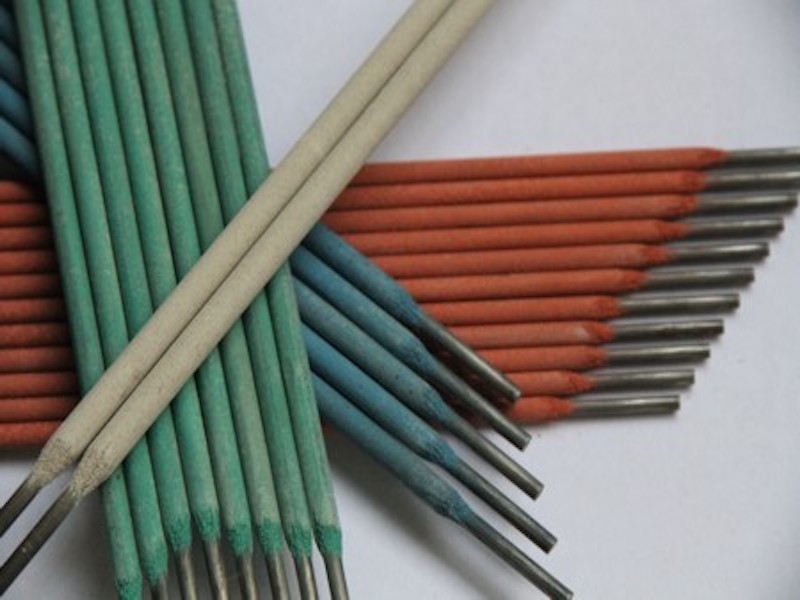

1. Discussing Types of Welding Rods:

There are several different types of welding rods available, each designed for specific welding applications. Here are some common types:

a) Mild Steel Welding Rods: These rods are the most commonly used and are suitable for welding mild steel. They have a high tensile strength and are versatile, making them suitable for a wide range of projects.

b) Stainless Steel Welding Rods: These rods are specifically designed for welding stainless steel. They offer excellent corrosion resistance and are commonly used in industries such as food processing, pharmaceuticals, and automotive manufacturing.

c) Aluminum Welding Rods: Aluminum welding rods are used to join aluminum and aluminum alloys. They have a low melting point, making them suitable for thin sections and aluminum repairs.

d) Cast Iron Welding Rods: These rods are specifically designed for welding cast iron. They have a high nickel content and are capable of withstanding the high heat associated with cast iron welding.

e) Flux-Cored Welding Rods: Flux-cored rods are similar to MIG welding wires, but they contain flux inside the wire. They are popular for their ease of use and high deposition rates, making them suitable for welding thick materials.

2. Buying Types of Welding Rods:

When buying welding rods, it is important to consider a few factors to ensure you choose the right type for your project:

a) Material Compatibility: The first consideration should be the type of metal you will be welding. Different welding rods are specifically designed for different metals. Ensure the rod you choose is compatible with the metal you are working with.

b) Project Requirements: Consider the requirements of your project, such as the level of strength, corrosion resistance, and appearance desired. Each type of welding rod offers different properties, so choose accordingly.

c) Diameter and Thickness: Welding rods come in various diameters, which impact the penetration and weld bead size. Thicker rods are suitable for heavier welds, while thinner rods are ideal for lighter applications.

d) Flux Type: If you opt for flux-cored welding rods, you need to consider the type of flux. Some fluxes provide better protection against atmospheric contaminants, while others produce cleaner welds.

3. Price of Types of Welding Rods:

The price of welding rods varies depending on the type, brand, and quantity. While specific prices may fluctuate, here’s a general idea of the price ranges you can expect:

a) Mild Steel Welding Rods: These are the most economical welding rods and are widely available at affordable prices. Generally, a pack of 10 rods will cost around $10-$15.

b) Stainless Steel Welding Rods: Stainless steel rods are slightly more expensive than mild steel rods, ranging from $15 to $25 for a pack of 10 rods.

c) Aluminum Welding Rods: Aluminum rods can be moderately priced, with packs of 10 rods ranging from $15 to $30, depending on the brand and quality.

d) Cast Iron Welding Rods: Due to their specialized nature, cast iron welding rods tend to be more expensive than other types. Expect to spend around $20 to $40 for a pack of 5 rods.

e) Flux-Cored Welding Rods: The price of flux-cored rods varies depending on the size and quantity. On average, a spool of flux-cored welding wire can range from $15 to $30.

Conclusion:

Choosing the right type of welding rod is crucial for achieving high-quality welds. Understanding the different types available and considering factors like material compatibility, project requirements, diameter, and flux type will help you make an informed decision. While the price of welding rods may vary, it’s important to invest in quality rods that meet your specific project needs. By doing so, you’ll ensure the durability and strength of your welds for years to come.