An Essential Guide

Introduction:

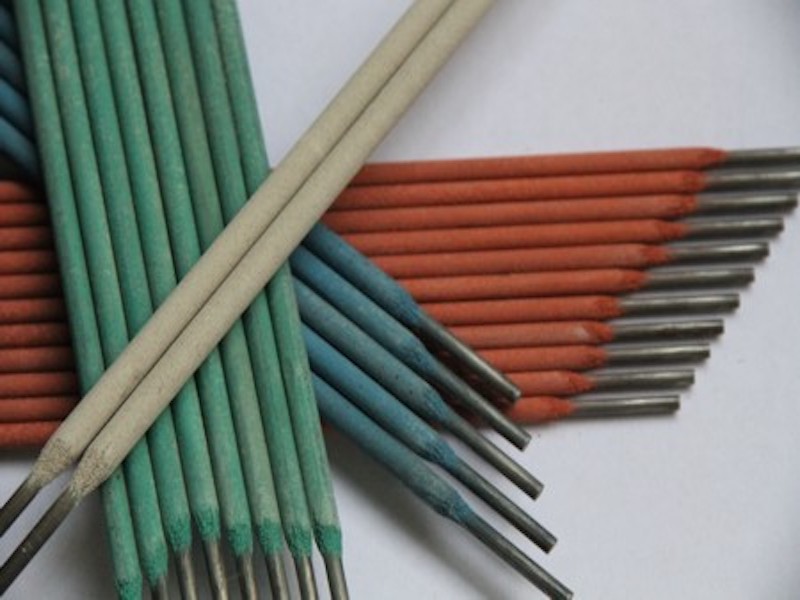

Welding electrode material is a crucial element in the welding process, playing a significant role in creating strong and reliable welds. Choosing the right welding electrode material is essential to ensure successful welding operations. This article will discuss the different types of welding electrode materials, factors to consider when purchasing them, and the price range of these materials.

I. Discussing Welding Electrode Material:

Welding electrode material refers to the consumable filler metal used in the welding process. It is typically coated with a flux that protects the weld pool from impurities, stabilizes the arc, and improves overall weld quality. Electrode material can be categorized into three main classifications: mild steel, stainless steel, and special alloys.

1. Mild Steel Electrodes:

Mild steel electrodes are the most commonly used type, suitable for welding low-carbon or mild steel. They offer excellent weldability, affordability, and versatility. These electrodes are ideal for automotive, construction, and general fabrication applications. Mild steel electrodes produce welds with good strength and a smooth appearance.

2. Stainless Steel Electrodes:

Stainless steel electrodes are specifically designed to weld stainless steel and provide excellent corrosion resistance. They are suitable for welding austenitic, martensitic, and ferritic stainless steel grades. Stainless steel electrodes offer high strength and durability, making them ideal for applications where resistance to heat, chemicals, or moisture is crucial.

3. Special Alloy Electrodes:

Special alloy electrodes are used when welding metals with unique properties or when additional strength and wear resistance are required. Some examples of special alloy electrodes include those used for welding high-strength steels, cast irons, and nickel-based alloys. These electrodes are often utilized in specialized industries such as aerospace, power generation, and oil and gas.

II. Buying Welding Electrode Material:

When purchasing welding electrode material, several factors need to be considered to ensure the most suitable choice for specific welding applications. These factors include the type of base metal to be welded, the welding process used, and the environmental conditions the weld will be exposed to.

1. Base Metal Compatibility:

The base metal compatibility is a crucial consideration when selecting the welding electrode material. Different metals have varying melt temperatures and chemical properties, which influence the choice of electrode material. Ensure that the electrode material is compatible with the base metal to achieve optimal welding results.

2. Welding Process:

Different welding processes, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and tungsten inert gas welding (TIG), require different types of electrode materials. Consult welding experts or material suppliers who can provide guidance on the suitable electrode material for specific welding processes.

3. Environmental Conditions:

The environmental conditions, such as temperature, humidity, and exposure to chemicals, should also be considered when selecting electrode material. Some materials offer better resistance to corrosion, high temperatures, or severe weather conditions, ensuring the longevity and reliability of the welds.

III. Price of Welding Electrode Material:

The price of welding electrode material varies depending on factors such as material type, brand, quality, and quantity purchased. Generally, mild steel electrodes are more affordable compared to special alloy or stainless steel electrodes. However, it is essential to strike a balance between cost and quality to ensure optimal welding performance.

1. Material Type and Brand:

Different manufacturers offer welding electrode materials with varying quality levels and pricing. Premium brands may offer higher quality materials that yield stronger and more reliable welds, while budget-friendly options may be suitable for less critical applications. Consider the intended use and budget when selecting the material type and brand.

2. Quantity Purchased:

Bulk purchases of welding electrode materials often result in cost-saving benefits. Suppliers may offer discounted prices for larger quantities, making it more economical for businesses or individuals involved in frequent welding operations.

Conclusion:

Choosing the appropriate welding electrode material is crucial for achieving strong and reliable welds. Considering factors such as base metal compatibility, welding process, and environmental conditions is essential when buying electrode material. While prices can vary, it is crucial to balance cost and quality to ensure optimal welding performance. By understanding welding electrode materials and their applications, individuals and businesses can make informed decisions and improve the quality of their welding operations.