Enhancing Efficiency and Precision in Welding Processes

Introduction:

Welding is an integral process in various industries, enabling the joining of materials and structures. Over the years, advancements in welding technology have led to the development of different welding consumables, including subpowder CO2 welding wires. These wires have gained popularity due to their ability to enhance efficiency and precision in the welding process. In this article, we will discuss subpowder CO2 welding wires, including their benefits, considerations when buying, and the typical price range.

Discussing Subpowder CO2 Welding Wires:

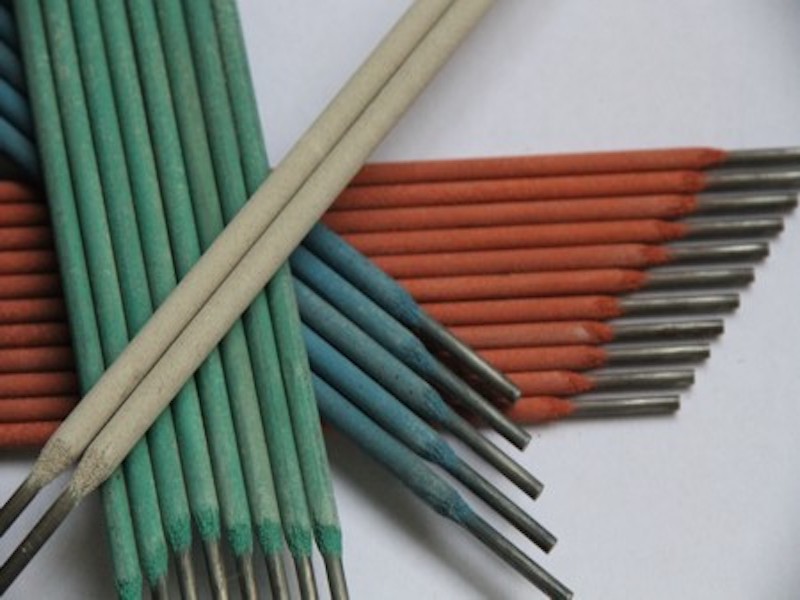

Subpowder CO2 welding wires, also known as flux-cored wires, are a type of welding consumable specifically designed for CO2 gas shielded welding processes. These wires are filled with a flux compound which protects the weld pool from atmospheric contamination during the welding process.

The flux-core in subpowder CO2 welding wires offers several advantages over solid welding wires. This includes improved penetration, reduced spatter, and enhanced bead appearance. A significant benefit of using subpowder CO2 welding wires is their high deposition rate, which translates to increased productivity and reduced labor costs.

Buying Subpowder CO2 Welding Wires:

When considering the purchase of subpowder CO2 welding wires, several factors should be taken into account to ensure optimal performance and long-term value.

1. Wire Diameter and Material Compatibility:

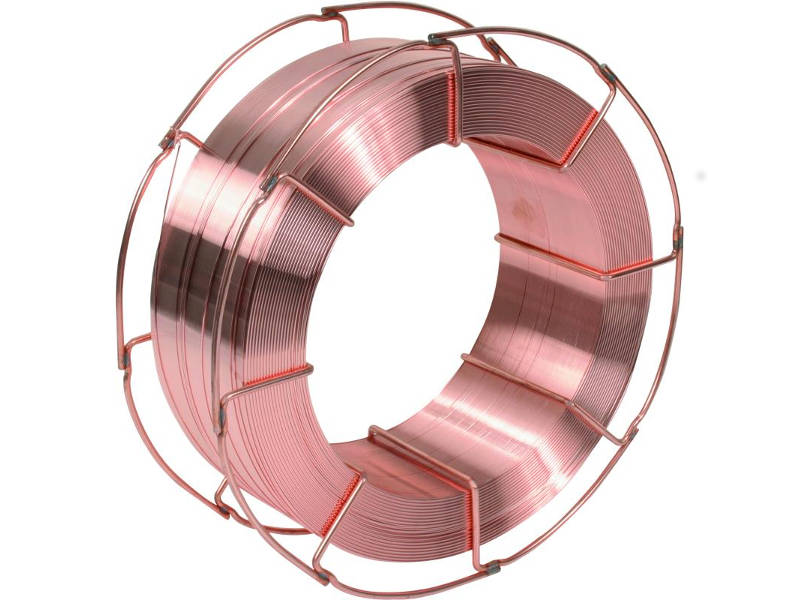

Subpowder CO2 welding wires typically come in various diameters to suit different applications. Determine the appropriate wire diameter based on the thickness of the materials you will be welding. Additionally, consider the type and composition of the base metal to ensure compatibility with the welding wire.

2. Flux Composition:

Different subpowder CO2 welding wires are formulated with specific flux compositions to address various welding applications. Consider the specific welding requirements of your projects, such as the desired weld appearance, corrosion resistance, and mechanical properties. Consult with welding professionals or the wire manufacturer to choose the right flux composition for your needs.

3. Quality and Certifications:

Always prioritize purchasing subpowder CO2 welding wires from reputable manufacturers that adhere to strict quality control measures. Look for wires that meet industry standards and certifications, such as ISO certifications and AWS specifications. Investing in high-quality products ensures consistent and reliable performance.

Price of Subpowder CO2 Welding Wires:

The cost of subpowder CO2 welding wires can vary depending on factors such as wire diameter, length, composition, and brand. On average, the price range for a standard 1kg spool of subpowder CO2 welding wire is between $10 and $25.

It is essential to remember that while price is a consideration, it should not be the sole determining factor in making a purchase. Durability, performance, and reliability are crucial factors that can significantly impact the overall value of the welding wires. Cheaper options may save money upfront, but their performance and lifespan might be compromised, resulting in increased cost and potential reworks or repairs.

Conclusion:

Subpowder CO2 welding wires provide a reliable and efficient solution for various welding applications. Their flux-core composition offers numerous benefits such as improved penetration, reduced spatter, and enhanced bead appearance. When purchasing subpowder CO2 welding wires, consider factors such as wire diameter, material compatibility, flux composition, and quality certifications to ensure optimal performance and value for your welding projects. While price is a factor, prioritize quality and reliability to achieve consistent and excellent welding results.In conclusion, subpowder CO2 welding wires are a valuable asset in the welding industry, offering enhanced efficiency and precision in the welding process. By using these flux-cored wires, welders can achieve improved penetration, reduced spatter, and enhanced bead appearance. The high deposition rate of subpowder CO2 welding wires also contributes to increased productivity and reduced labor costs.

When purchasing subpowder CO2 welding wires, it is important to consider several factors. First, the wire diameter should be suitable for the thickness of the materials being welded. Additionally, compatibility with the base metal should be ensured by considering the type and composition of the materials. The flux composition of the welding wire should also be carefully selected based on the specific requirements of the welding projects, such as desired weld appearance, corrosion resistance, and mechanical properties.

Quality and certifications play a vital role in the selection process. Always choose reputable manufacturers that adhere to strict quality control measures. Look for subpowder CO2 welding wires that meet industry standards and certifications, such as ISO certifications and AWS specifications. Investing in high-quality products ensures consistent and reliable performance, reducing the risk of rework and repairs.

While price is a consideration when purchasing subpowder CO2 welding wires, it should not be the sole determining factor. Cheaper options might save money upfront, but their performance and lifespan may be compromised, leading to increased costs in the long run. Prioritize durability, performance, and reliability to achieve cost-effective welding results.

In terms of pricing, the cost of subpowder CO2 welding wires can vary depending on factors such as wire diameter, length, composition, and brand. On average, a standard 1kg spool of subpowder CO2 welding wire ranges between $10 and $25. However, it is essential to remember that the overall value of the welding wires is more significant than the initial cost. Investing in high-quality subpowder CO2 welding wires ensures reliable performance and contributes to the success of welding projects.

In conclusion, subpowder CO2 welding wires offer significant advantages in the welding industry, including improved efficiency and precision. When buying these welding wires, it is essential to consider factors such as wire diameter, material compatibility, flux composition, and quality certifications. While price is a factor, prioritize quality and reliability to achieve consistent and excellent welding results. By selecting the right subpowder CO2 welding wires, welders can ensure optimal performance, productivity, and value for their welding projects.